Process Control in '24: 4 Benefits & 5 Practical Advices

According to business process management stats , 62% of businesses already use one or two software to manage their processes. Process control is one of the steps in the broader process management cycle that helps companies achieve high process performance by improving efficiency, effectiveness and compliance.

However, 15% of business leaders do not believe their processes are well-measured and managed, which often stems from a lack of knowledge as to why and how processes should be controlled. .

Therefore, this article will answer questions such as:

- What process control is?

- How does process control work?

- What are the benefits of process control?

- How can process mining ease process control for businesses that want to develop accurate process control plans?

What is process control?

Process control constantly monitors and changes out-of-control processes to ensure that operations are not interrupted.

Industries such as manufacturing, chemicals, oil and gas, and mining all require tight process controls. These real-time like checks ensure safety of workplace, increase efficiency and improve the level of compliance for the organization.

How does process control work?

There are three common steps in process control :

- Setting a target value: Engineers or process analysts set target values for process parameters, such as optimal temperature, so that process controls can correct when these parameters deviate from the desired value.

- Creating an action plan: Analysts also create a detailed action plan, a corrective procedure for the cases when a process is out of control, known as out-of-control Action Plans (OCAPS).

- Developing process control systems: The company develops a customized process control system to check the flow, conditions, output and other aspects of a process. These process control systems can be manual or automatic:

- Manual process control requires a human operation team to constantly monitor the process parameters and make adjustments when necessary. For example, an operations manager at a bank constantly monitors transaction reports and the accuracy of the processes.

- Automatic process control requires businesses to implement sensors and software that control the process parameters, send warnings to the operation team, or automatically correct the conditions. For example, a manufacturer settles a factory sensor to receive feedback on the plant’s functioning.

Leverage process mining for process control

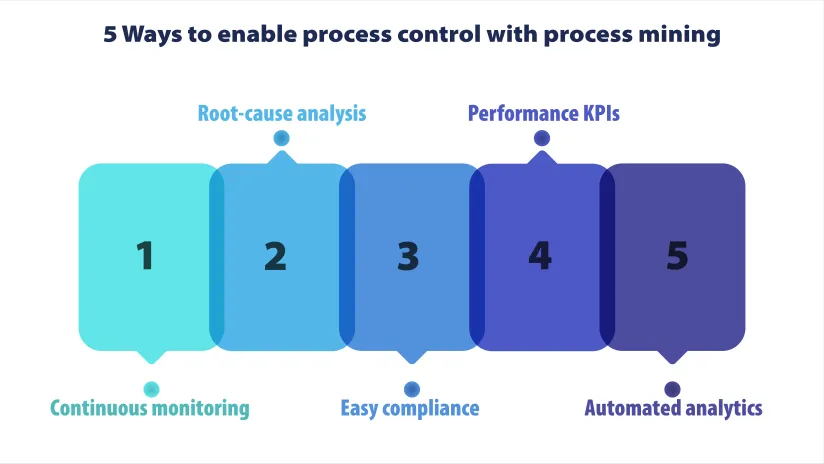

Process mining can facilitate process control since it offers the following:

1. Continuous monitoring

Process mining extracts, discovers and models process data, enabling users to gain an end-to-end understanding of their processes. Process analysts, operators or business leaders can use these models to track the process functioning and identify bottlenecks.

2. Root-cause analysis

Some process mining tools offer automated root-cause analysis to investigate the root-cause behind the problems that occur across a process.

3. Easy compliance

As process mining trends suggest, audit and compliance checks are one of the top 5 use cases of process mining because the software contains a core capability, called conformance checks, that compares two process models – the discovered as-is model against the ideal, as-if models. Therefore, users can detect the areas where deviations from rules and regulations occur.

4. Performance KPIs

Process mining includes process KPIs dashboard, which can be useful for process control purposes. Analysts can track their process performance in terms of cost and time management to improve their productivity.

5. Automated analytics

Most of the time, data cleaning and wrangling is the most effort-demanding phase of a data mining project, which is why businesses may hesitate pushing for using extensive data produced by sensors and other systems. Process mining employs ML algorithms to find patterns and model the data so that the firms can have their employees’ time be spent on other valuable tasks.

Why is process control important?

Some benefits of controlling your processes include:

1. Ensuring safety

A minor deviation in parameters can lead to drastic differences in the process which may threaten the workplace safety. For example, a small change in boiler pressure can threaten the workers’ safety for a chemical manufacturer.

Process control makes sure that human operators or computer systems constantly monitor the processes to find such non-conforming conditions. As a result, the companies that firmly apply process control can prevent these small errors with devastating scenarios.

2. Achieving energy efficiency

Process control allows strategists to evaluate the energy utilized to complete the workflow. Based on the calculations, they can drive data-driven decision-making to reallocate resources and rethink their internal energy consumption. Not only does energy efficiency reduce costs but it also achieves sustainability.

For instance, a manufacturer can estimate the energy consumption of plants used in the factory. According to the results, the manufacturer can detect the optimum levels that provide the highest quality with the lowest waste and install new machinery.

3. Reducing costly errors

To check processes, one must constantly monitor them. Such monitoring allows for detecting inefficiencies, such as reworks,potential problems, and machinery scraping before they occur, which can avert costly mistakes.

For a manufacturer, noticing a fault in the machinery and replacing the necessary parts can prevent costly scenarios and product waste.

4. Improving customer experience

Monitoring and adjusting process parameters creates smooth and accurate processes, which improves the service or product that the given process produces. As a result, the company can enhance customer experience by ensuring that the processes work at the ideal level.

For instance, a retailer that benefits from process control to assess the performance of their delivery operations can identify areas for change and improvement. When the firm notices bottlenecks that lead to late product delivery and implements a change, the customers will be more likely to re-use their services.

Further reading

Explore more on process management and improvement:

- 6 Ways to Benefit from Business Process Management

- What is Process Technology & 3 Reasons to apply it?

- Pair Methodology with Technology for Process Improvement

If you want to benefit from process mining, you can review our data-driven and comprehensive vendor list for process mining.

Take full control of your processes by managing them with top workflow and task management tools such as:

- Workflow management software

- Business process management software

- Low-code/No-code development platform

- Onboarding software

If you need more help, let us help you to find the right vendor:

Comments

Your email address will not be published. All fields are required.