Companies that foster corporate sustainability through digital transformation are likely to be tomorrow’s leaders. Although supply chain sustainability technologies are beneficial for businesses, some managers have a lack of information regarding their implementations.

To close the information gap, explore the top 6 technologies that supply chain executives can use to reduce their GHG emissions and social externalities, while increasing their operational efficiency:

1. Public-cloud enterprise resource planning (ERP) tools

Supply chain sustainability technology

Public cloud ERP systems empower supply chain executives to measure and manage environmental impact, integrating real-time financial and operational data across the entire value chain. This holistic view helps executives identify bottleneck points and improve supply chain management, all from any location with internet access.

Automating carbon footprint calculation

Some public cloud ERP systems that specialize on environmental aspects automate calculating product and organizational carbon footprints. These tools use operation-specific emission factor assumptions, such as those provided by the US Environmental Protection Agency, to estimate carbon emissions for various supply chain activities.1 For example, if the field sales team consumes 27,000 gallons of gasoline, the ERP system can calculate that this usage results in approximately 240 tons of CO2 emissions. This data intelligence allows executives to develop strategies for reducing greenhouse gas emissions across their supply chains.

Operational efficiency and carbon footprint

Cloud technology products not only streamline supply chain processes but also contribute to improved energy efficiency. Running ERP solutions on public cloud platforms minimizes the company’s carbon footprint, thanks to the increased efficiency and use of renewable energy by large cloud providers. According to Accenture, if global supply chains operated exclusively on public clouds, annual GHG emissions could be drastically reduced, equivalent to removing 22 million cars from the road.2

Sustainability reporting and corporate sustainability

Public cloud ERP systems improve sustainability reporting by providing accurate and automated data on carbon footprint changes across the entire supply chain. By monitoring and reporting on their environmental impact, companies can pursue long-term business transformation, aligning with sustainable development goals and gaining a competitive advantage.

Environmental impact of ERP system deployment

The choice of where to host ERP systems also affects the sustainability impact. On-premise installations tend to have a larger carbon footprint compared to public cloud deployments, which benefit from the energy efficiency and green energy sources of cloud providers.3

The below video shows how digital supply chains improve corporate sustainability.

2. Smart devices

Smart sensors, drones, telematics, and self-driving automobiles are or will be used to mitigate the environmental impact of supply chain operations:

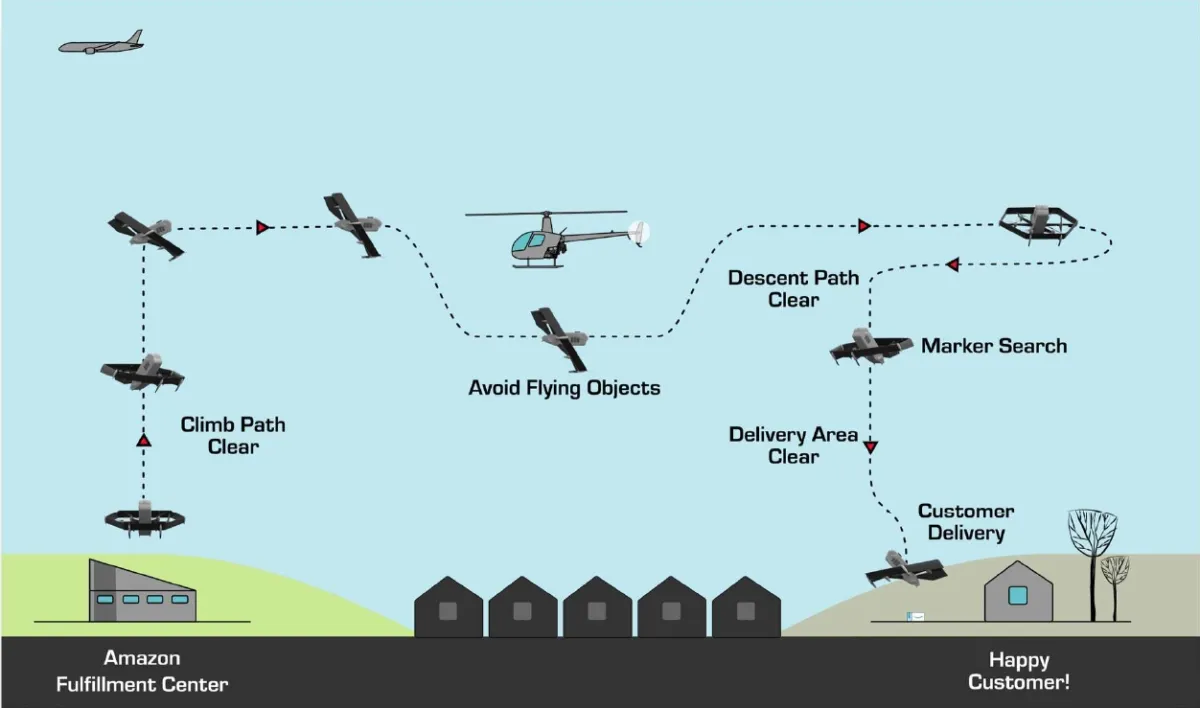

Drones

Last-mile delivery is a significant supply chain operation that impacts customer satisfaction, variable costs, and GHG emissions. Drones can reduce both variable-total costs of last-mile delivery and GHG emissions compared to traditional methods if there are more than 200 consumers in the area.4 At the same time, drones can provide faster delivery. Amazon delivers products using drones to obtain a competitive advantage in this area.5

Figure 1. Amazon Prime drone delivery operation

Source: Amazon6

Smart sensors

Supply chain greenhouse gas emissions, including warehouse emissions, is responsible for 13% of global greenhouse gas emissions.7 A median warehouse, on the other hand, can lower its GHG emissions by roughly 30% by employing led lights, smart sensor based lighting, and smart HVAC (heating, ventilation, and air conditioning) systems.8

Telematics

Telematics can be used to track the condition of a vehicle and the actions of its driver (for instance, driving with low rpm reduces fuel consumption). Transportation accounts for ~30% of 2022 U.S GHG emissions.9 Any degradation on a truck’s tyres or engine might result in inefficiencies, resulting in increased fuel consumption. Supply chain administrators can significantly reduce oil use by watching trucks and drivers 24/7. The Michelin Effifuel project, for example, employed this method and reduced oil consumption by over 2 liters per 100 kilometers.10

Self-driving vehicles: Since the driver compartment will be used as an additional storage area, self-driving vehicles will minimize GHG emissions by carrying more items per trip.11 Additionally, connectivity between these IoTs aids in route and traffic optimization in sustainable supply chain management. As a result, self-driving vehicles will save costs and GHG emissions.

The ubiquity of smart devices can also be used for more accurate environmental impact measurement. The environmental impact estimates that we mentioned in the ERP section can have significantly higher accuracy when field data is used to measure actual environmental impact.

3. 3D printers

With 3D printing technology, goods can be manufactured wherever printers are located by using a digital file like CAD models. Thus, additive manufacturing offers several opportunities for supply chain executives in terms of lowering transportation costs, reducing GHG emissions, and saving time.

Additive manufacturing saves time and reduces GHG emissions

Companies can computerize their intermediate goods and recreate them in the next production location using digital code thanks to 3D printing. As a result, they can save time and money and reduce GHG emissions by using email instead of using the postal service.

3D printers, similar to email, are more environmentally beneficial when used in smaller quantities and across longer distances. Supply chain executives can identify the distinctive intermediary goods that come from far and in smaller quantities to maximize the benefits of additive manufacturing.

Real-life examples of the effect of 3D printing on sustainability

Anglo American, a mining business, collaborates with a 3D printing vendor to optimize its sustainable supply chain. They have digitized mining rock drill bits and transmit digital files to the mining field instead of real drills.12

To effectively use 3D printers, Airbus partnered with Materialise, a Belgium-based technology company that specializes in additive manufacturing.13 According to Airbus, additive manufacturing technology can reduce an A320 plane’s annual GHG emissions by around 465,000 metric tons, which is roughly the same as eliminating 100,000 automobiles from the road for a year.14

The video below illustrates how 3D printing can enhance your corporate sustainability.

4. Electric vehicles (EV)

Electric vehicles can drastically reduce GHG emissions without a negative impact on supply chain operations if the majority of the electricity in a location is generated by green energy sources and adequate charging infrastructure is in place.

Companies can replace traditional fleets and attract more investors with their greater ESG reporting scores. Furthermore, businesses do not need to consider how to organize charging activities. There are e-mobility tools that alert EV owners to charging stations that are ready to use, as well as EV owners to return their vehicle to a regular parking space after it is fully charged.

Real-life examples of the impact of EV on sustainable supply chains

DHL, as one of the largest logistic companies, reduced its GHG emissions by 1.3 tons by 2023 by utilizing +36K electrical vehicles.15 The company aims to achieve net zero GHG emissions by 2050.

EVs are also effective in the last mile of delivery. DHL Express’s deployment of 16 electric vans for first-and-last-mile deliveries in Bangkok supports its commitment to sustainability by reducing CO2 emissions by 436 tons annually.16

5. AI/ML models

Artificial intelligence models and machine learning algorithms are good at optimization and forecasting which are effective for reducing GHG emissions while enhancing operational efficiency. PwC approves this claim and predicts that AI/ML models will boost the world economy by 4.4% while reducing GHG emissions by around 4%.17

Real-life examples of AI/ML models for corporate sustainability

The UPS On-Road Integrated Optimization and Navigation (ORION) effort is an example of how AI/ML models can help supply chains become more sustainable.18 By minimizing turns, the model optimizes the route to ensure the least amount of oil usage. UPS decreases its miles by around 8 for each route and reduces its annual carbon impact by the equivalent of eliminating 20 million cars from the road thanks to the initiative.

AI/ML models can also be used to forecast demand. By forecasting demand accurately, businesses can organize their warehouses and reduce the network distance in a more sustainable manner. A global fast-food chain used AI procurement software and analyzed market demand and supplier capabilities, enabling the chain to reduce network distance and GHG emissions by 25%.19

It is important to note that companies do not need to develop their own AI/ML models; lots of cloud systems serve businesses with route optimizer, traffic optimizer, and loading optimizer tools.

6. Blockchain

Thanks to the digital transformation, blockchain technology allows transparent data flow between different parties, such as various suppliers and end users. With this capability, blockchain can help companies assess:

- Product carbon footprint

- Circularity of their business

- Compliance with ESG standards and laws

- Social externalities and discrimination that occur through the value chain

- Product quality

A real-life example of the blockchain impact on supply chain sustainability

Renault tracks its supply quality by extracting data from its suppliers via blockchain. Thanks to blockchain technology, Renault decreases the cost of non-compliance by 50%.20 The company also considers using blockchain to collect transparent data from customers to calculate circular economy metrics such as recycle rate.

To learn more about how blockchain technology transforms supply chains, you can read our Blockchain in Supply Chain: 12 Case Studies article.

You can also check our supply chain software list to find tools that improve your supply chain sustainability.

How digitalization supports supply chain sustainability

Digitalization helps make supply chains greener, faster, and fairer.21

Cutting waste, saving time, and lowering emissions

Digital tools help make supply chains more efficient. They reduce extra inventory, cut down on waste, save time, and lower both costs and environmental impact. But it’s also important to make sure that people in the least developed countries (LDCs), many of whom are still offline, are not left behind. Sustainable progress must include everyone.

Better trade through paperless processes

Digitalizing trade procedures can make supply chains greener and more inclusive. Going paperless saves resources and speeds things up. According to the UN’s ESCAP, fully digitalizing trade rules could cut 32–86 kg of CO₂ emissions per transaction. Across Asia and the Pacific, this could mean saving 13 million tons of CO₂, like planting 439 million trees.22

Real-world examples:

- Vanuatu: Digital systems reduced the time to issue bio-security certificates from 6 days to just 10 minutes. Paperwork dropped by 95%, and emissions fell by 5,827 kg.23

- Timor-Leste: A new electronic system cut 90% of physical trips between agencies and reduced printed customs documents by 80%. This saved 14,492 kg of CO₂.24

- Cambodia: A digital interface between customs and postal services sped up small business parcel shipments, helping micro and small businesses benefit from global e-commerce.25

Improving business processes for sustainability

Digital tools also improve how businesses work. They allow for smarter, faster, and more flexible production, which supports sustainability goals.

Case study:

- Bhutan: A project called “e-infrastructure for trade and services” helped digitize the potato trade. This included machine grading and online auctions. It boosted price transparency, reduced unfair practices, and cut transaction costs.26

The bigger picture

Digitalization helps build greener, more efficient supply chains. But to truly support global sustainability, everyone must have access to these tools. Including the offline population in LDCs is essential for fair and lasting progress.

External Links

- 1. Greenhouse Gases Equivalencies Calculator – Calculations and References. U.S. Environmental Protection Agency. Accessed: September/4/2024.

- 2. Sustainability Consulting Services & Solutions | Accenture.

- 3. Sustainability Consulting Services & Solutions | Accenture.

- 4. Chiang, W. C., Li, Y., Shang, J., & Urban, T. L. (2019). Impact of drone delivery on sustainability and cost: Realizing the UAV potential through vehicle routing optimization. Applied energy, 242, 1164-1175.

- 5. Amazon drones: Prime Air expands drone deliveries after FAA approval. US About Amazon

- 6. Prime Air – FAA Exemption Petition (16JUL19). Amazon.

- 7. Ries, J. M., Grosse, E. H., & Fichtinger, J. (2017). Environmental impact of warehousing: A scenario analysis for the United States. International Journal of Production Research, 55(21), 6485-6499.

- 8. King, J., & Perry, C. (2017). Smart buildings: Using smart technology to save energy in existing buildings (pp. 1-46). Washington, DC, USA: Amercian Council for an Energy-Efficient Economy.

- 9. Sources of Greenhouse Gas Emissions | US EPA.

- 10. EFFIFUEL™ from MICHELIN® solutions Delivers Fuel Savings – Motorindia.

- 11. Inbound Logistics | January 2024 - Page 70.

- 12. Anglo American explores 3D printing technologies to boost supply chain efficiencies and support local businesses | Anglo American.

- 13. Bridging the gap with 3D printing | Airbus. Airbus

- 14. Pioneering bionic 3D printing | Airbus. Airbus

- 15. Sustainability - DHL - United States of America.

- 16. DHL Express leads the way in sustainable logistics with electrification of delivery fleet in Thailand | DHL Thailand.

- 17. How AI Can Enable a Sustainable Future. PwC.

- 18. UPS To Enhance ORION With Continuous Delivery Route Optimization. UPS.

- 19. Global Fast-Food Chain Develops Supply Risk Mitigation Strategy With GEP | GEP.

- 20. A new blockchain solution for the certification of vehicle compliance at European level will be implemented. Renault Group

- 21. How digitalization can drive sustainable supply chains | World Economic Forum.

- 22. Vanuatu shows how to reduce emissions through trade facilitation | UN Trade and Development (UNCTAD).

- 23. Vanuatu shows how to reduce emissions through trade facilitation | UN Trade and Development (UNCTAD).

- 24. Roadmap for trade single windows: UNCTAD helps countries cut red tape, costs and emissions | UN Trade and Development (UNCTAD).

- 25. Modernizing Cambodia's Customs Processes: EAD Launch for Cross-Border Trade - News - Site.

- 26. How digitalization can drive sustainable supply chains | World Economic Forum.

![5 Supply Chain Data Sharing Barriers & Best Practices ['25]](https://research.aimultiple.com/wp-content/uploads/2023/06/Supply-Chain-Data-Sharing-1-190x107.png.webp)

Comments

Your email address will not be published. All fields are required.