The concept of circular economy (CE) is quickly making its way into business literature since we are struggling with major environmental issues. Besides its environmental value, CE expects to bring 4.5 trillion dollars until 2030 due to effective allocation of resources.1

Since the circular economy (CE) concept is relatively new to many corporate agendas, executives may be uncertain about which circular economy metrics to report. Explore 12 key metrics for assessing corporate circularity:

12 metrics to measure corporate circularity

Before introducing general metrics, it is crucial to highlight the significance of industry-specific indicators. For instance, in the finance sector, a higher level of portfolio circularity is often correlated with greater circular economy (CE) maturity, as it reflects the institution’s commitment to environmental stewardship, which is considered a favorable investment metric.

Conversely, this metric holds little relevance for healthcare organizations, which should prioritize reducing hazardous waste due to its critical impact on their operations and regulatory compliance.

Recyclability-related metrics

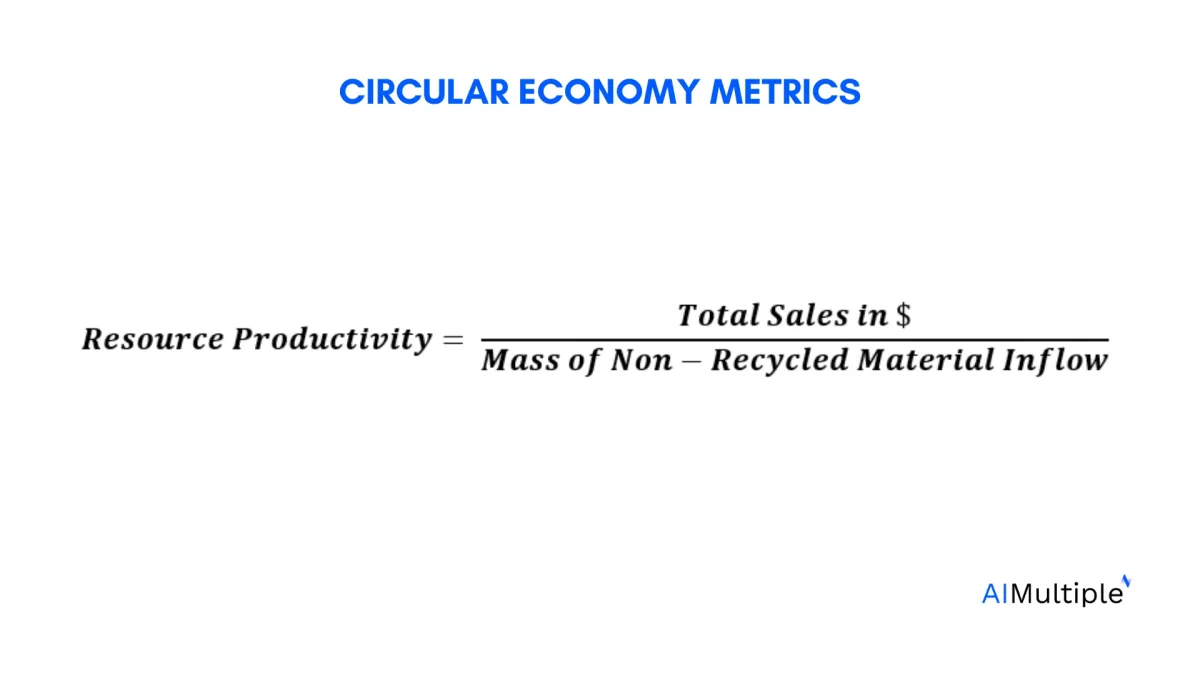

1. Resource productivity

Resource productivity is a key metric to evaluate how efficiently businesses utilize materials extracted from the Earth. A higher ratio indicates improved circularity and greater resource efficiency.

For example, when a car manufacturer uses virgin iron ore for sheet metal production, resource productivity can be measured by the dollar sales generated per unit of iron ore consumed. Higher productivity implies better circularity and operational efficiency.

Figure 1. The formula of resource productivity

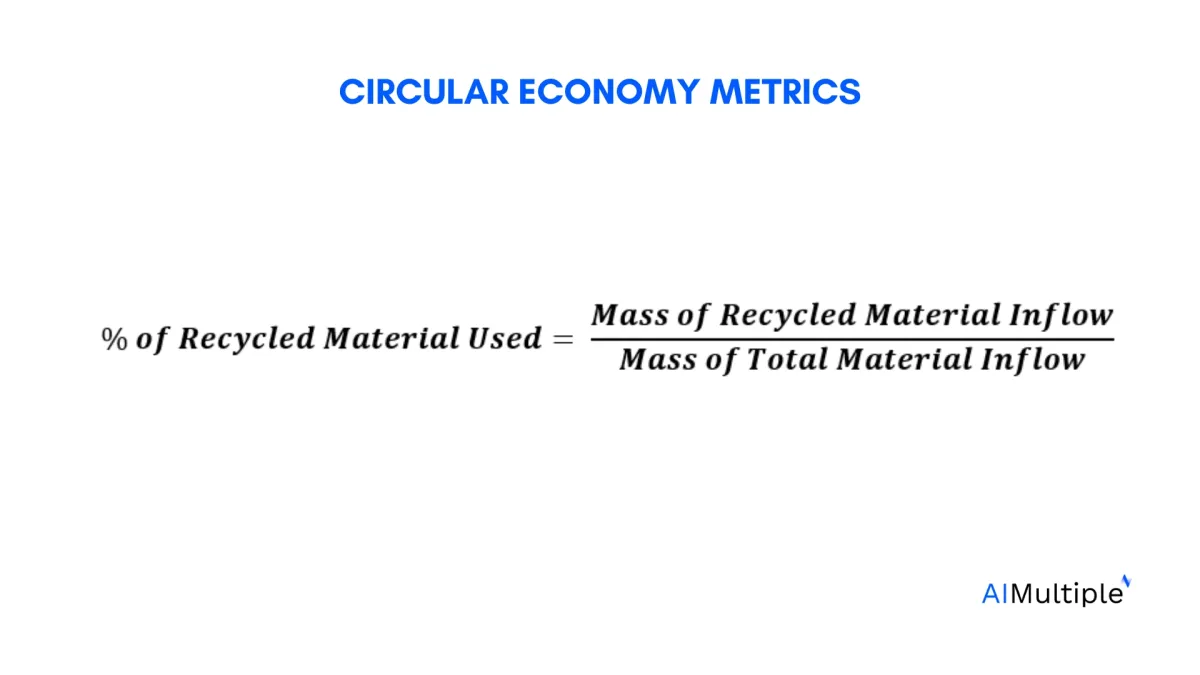

2. Percentage of recycled material used

There are two main sources that manufacturers derive raw materials from. They can use non-recycled resources of nature or they can renew consumed goods and materials into raw materials. This metric assesses the proportion of materials sourced from natural, non-recycled resources versus those derived from recycled or renewed materials.

A higher percentage of recycled materials reflects better alignment with circular economy principles. Many companies, such as H&M with its “Let’s Close the Gap” initiative, have embraced this approach. H&M’s goal is to use 100% sustainable raw materials by 2030, with 57% achieved in 2019.2

Figure 2. Formula of percentage of recycled materials

3. Percentage of product recyclability

To achieve a high level of circular economy integration, it is essential to design and produce goods with a high degree of recyclability. The percentage of product recyclability measures how much of a product’s materials can be reused or repurposed after its initial life cycle. Products made with biodegradable or easily recyclable materials are more likely to be reintroduced into the value chain, contributing to resource efficiency and reducing waste generation.

For businesses aiming to measure circularity, this metric is vital. The higher the recyclability of a product, the more it contributes to circular economy practices, where materials are kept in use for as long as possible. Although it can be difficult to measure the actual rate of product recycling, especially for consumer goods, companies can encourage consumers to recycle through incentive programs.

For example, deposit refund systems can motivate customers to return used products by offering a financial reward.3 This not only boosts recycling rates but also ensures that businesses maintain a focus on extending product lifecycles, a key component of circular economy frameworks.

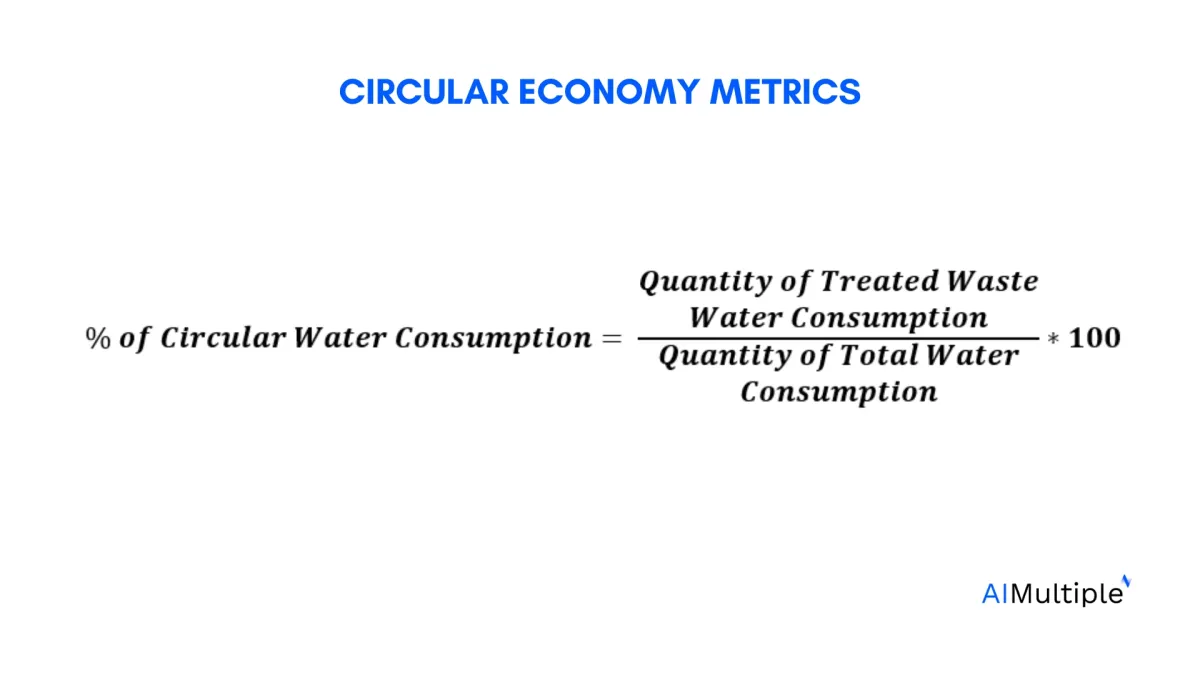

4. Percentage of circular water consumption

Water is a crucial resource, and ensuring its circular use is essential for businesses seeking to minimize their environmental impact. The percentage of circular water consumption refers to the proportion of water that is reused in a company’s operations rather than being sourced from fresh water supplies.

The greater the reuse of water, the more circular and sustainable the company’s practices.

This metric becomes increasingly important in the face of global water shortages. According to a report by McKinsey, water demand is projected to surpass drinkable water supplies by 40% by 2030 if current consumption patterns continue.4 Already, 35% of the global population lacks access to safe drinking water.(Water Scarcity. United Nations. Accessed: September/14/2024.)

Businesses, particularly in developed economies, consume a significant portion of available water resources, often without adequate reuse systems in place. Implementing circular water consumption practices, such as reusing treated wastewater, can significantly reduce freshwater consumption and contribute to global sustainability efforts.

Within industrial zones, companies can collaborate to reuse water across industries. For example, wastewater from a pasta manufacturer could be treated and reused by a chemical company, illustrating the potential for cross-industry cooperation in enhancing circularity.

Figure 3. Percentage of circular water consumption formula

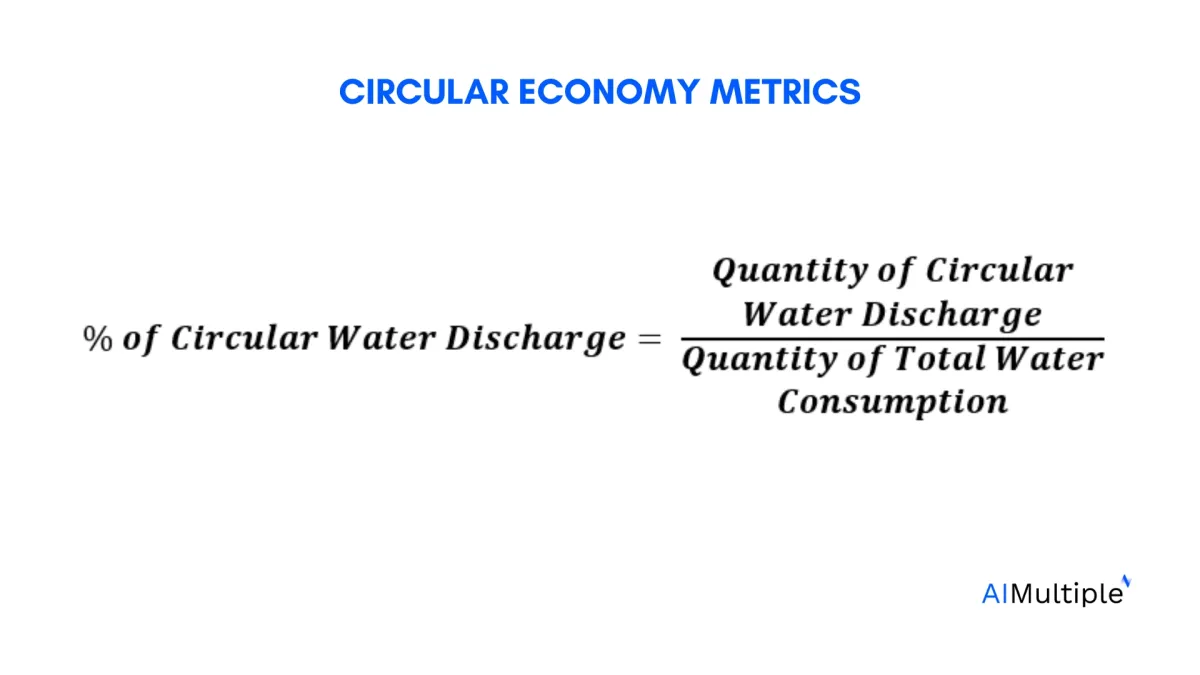

5. Percentage of circular water discharge

In addition to using water more efficiently, companies should focus on discharging water in a form that allows it to be reused by other businesses or sectors. The percentage of circular water discharge measures the proportion of water that can be safely reused after it is discharged from business operations.

This metric is closely aligned with the principle of resource balance in the circular economy, where what is taken from nature should be returned in a reusable form. A higher percentage of circular water discharge indicates that a company’s practices are more sustainable and contribute to broader circularity goals.

To achieve this, businesses must invest in facilities that treat water to a level suitable for reuse. This aligns with environmental standards like GRI 306, which provide guidance on water discharge and reuse practices, helping companies reduce their overall environmental footprint.5

Figure 4. Percentage of circular water discharge formula

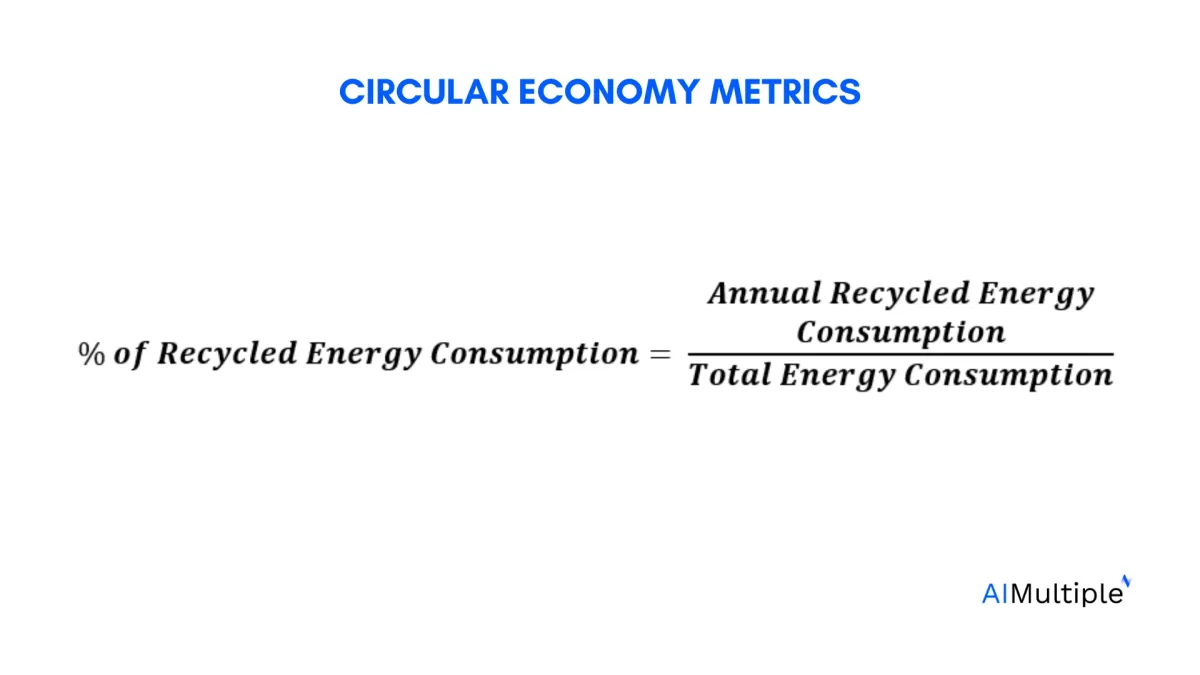

6. Percentage of recyclable energy consumption

The shift toward renewable energy sources is a central component of the circular economy. The percentage of renewable energy consumption measures how much of a company’s energy comes from renewable sources like wind, solar, or hydropower.

As companies move away from fossil fuels, they not only reduce their carbon footprint but also contribute to the circular economy by using resources that are replenishable and have minimal environmental impact.

Businesses and national organizations increasingly report their renewable energy usage, providing transparency and allowing stakeholders to track progress. For example, the U.S. Environmental Protection Agency (EPA) tracks the renewable energy consumption of retail enterprises, with many businesses aiming to increase their use of renewables to meet sustainability targets.6

A higher percentage of renewable energy consumption reflects a company’s commitment to reducing its reliance on non-renewable resources and addressing climate change.

Figure 5. Percentage of renewable energy consumption formula

7. Estimated environmental saving of rentals

Leasing goods and services can significantly reduce a company’s environmental impact by extending the life of products and reducing the need for new production. The estimated environmental savings of rentals are calculated by measuring how leasing contributes to reducing resource consumption and waste generation.

For instance, a company that leases vehicles rather than purchasing new ones can estimate the environmental savings by calculating the carbon footprint reduction achieved through reuse. This metric helps businesses measure their progress toward a more circular economy, where products are used for longer periods and resources are conserved.

8. Repairability of product

The repairability of a product is an important metric for promoting circular business models. Products that are easy to repair can be used for longer, reducing the need for new materials and minimizing waste. The greater the repairability, the more likely it is that consumers will extend the product’s life, enhancing resource efficiency.

Companies can improve product repairability by designing products that are easy to disassemble and ensuring that spare parts are readily available. This aligns with the circular economy’s focus on keeping products and materials in use for as long as possible, reducing the overall environmental impact of production.

9. Warranty period

A product’s warranty period often serves as an implicit indicator of its durability and circularity. Companies that offer long warranties signal confidence in the longevity of their products, which aligns with circular economy principles.

For example, Waterhaul, a sunglasses manufacturer, offers a lifetime warranty on its products, which are made from recycled materials like ghost fishing nets.7 This not only demonstrates the company’s commitment to sustainability but also encourages consumers to use products for longer, reducing waste generation.

Overall progress/situation assessment metrics

10. Progress towards goals

Tracking progress towards established circular economy goals is essential for businesses to measure their transition to more sustainable practices. Companies that set clear targets for circularity, such as increasing the percentage of recycled materials or reducing waste, can use this metric to monitor progress and communicate successes to stakeholders.

For example, H&M’s goal of using 100% recycled raw materials by 2030 can be tracked by measuring annual changes in the percentage of recycled materials used in production. This helps companies, investors, and consumers evaluate the effectiveness of circular strategies and adjust them as necessary.8

11. Circle assessment

The circle assessment tool provides businesses with an easy-to-use, online self-assessment to diagnose how their current practices align with circular economy objectives. It allows companies to evaluate different operational and organizational aspects, from implementing recycling schemes to developing new business models.

The tool scores companies based on their current circular practices and educates employees on potential circular opportunities.

Figure 6. An example of circle assessment

Source: Circle Economy9

This metric can be used across multiple business divisions or for the organization as a whole, offering a comprehensive overview of a company’s progress towards circularity. As a guiding framework, the Circle assessment helps businesses focus on areas where circular transitions are needed and provides insights into how to accelerate sustainability initiatives.

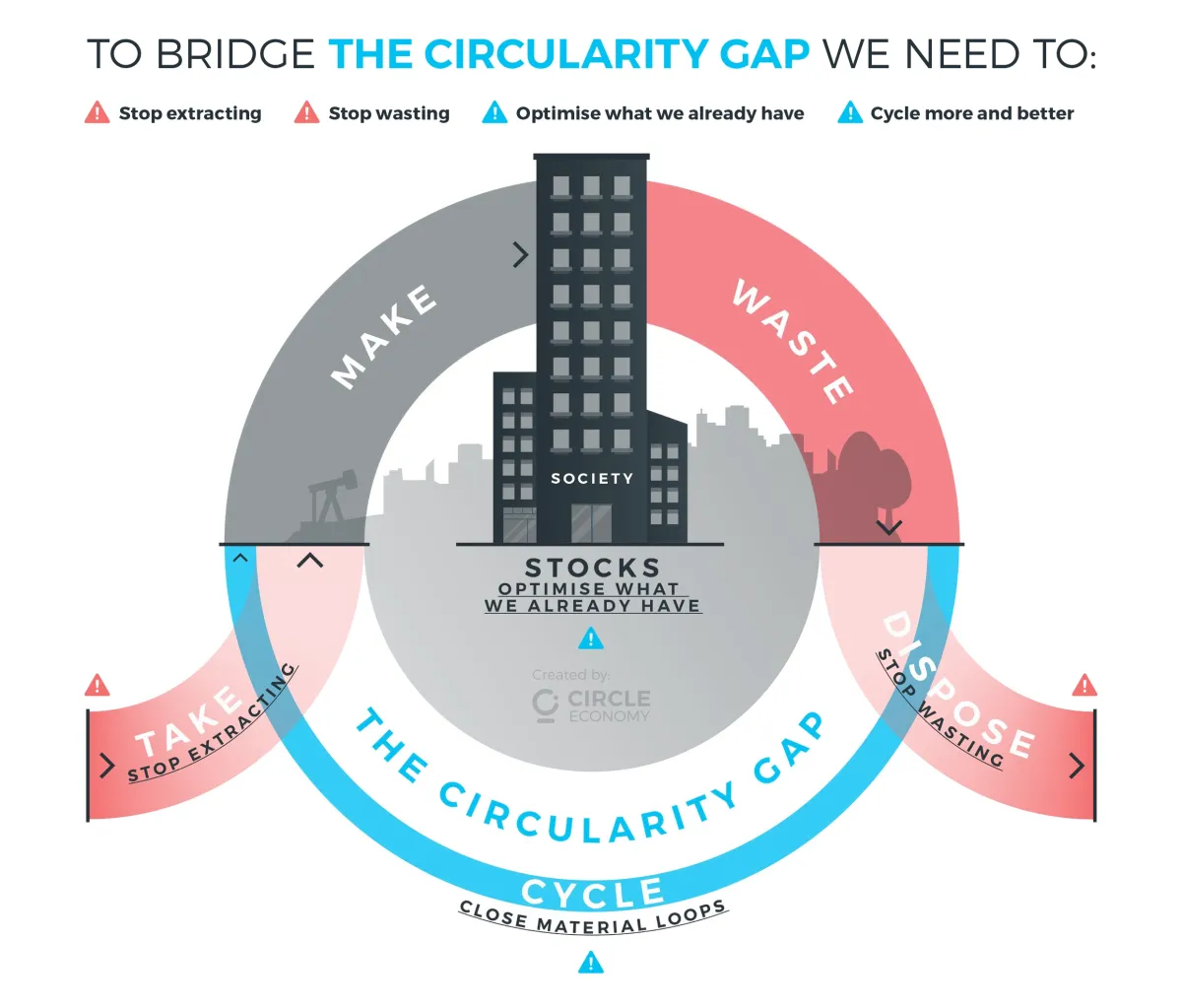

12. Circularity gap metric

The circularity gap metric focuses on measuring the share of circular materials in a value chain. This single metric highlights the proportion of materials that are still being wasted instead of being reused or recycled. The inverse of this metric, known as the circularity gap, measures the extent to which materials are not circulated within the value chain.

Figure 7. Visual representation of the circularity gap

Source: Circle Economy10

This metric serves as a key indicator for businesses to measure progress in transitioning towards a circular economy. It is particularly useful for raising awareness about the need to reduce waste and improve resource management.

While the Circularity Gap Metric provides a high-level overview, it can be complemented by other tools such as Circulytics11 or Circular Transition Indicators12 (CTI) to gain deeper insights into specific interventions required to enhance circularity within a company or its product lines.

Advantages of measuring circularity of firms

1. Enables development of a circular economy strategy

Measuring circularity allows businesses to identify inefficiencies in their resource consumption and waste management systems, enabling the design of targeted plans to address these challenges. Circular economy metrics provide valuable insights for optimizing resource efficiency by leveraging innovation and technology, leading to enhanced operational performance and sustainability.

2. Promotes proactive business practices

There is evidence highlighting the growing awareness among investors, customers, and other stakeholders regarding environmental, social, and governance (ESG) issues.

- Recent market research indicates that %46 of customers prefer to buy “more sustainable products or products with a reduced climate effect” while shopping.13

- The value of firms can be determined by the investment community, which prefers ESG investing by prioritizing ESG initiatives and data of firms while making investments.14

Using consistent circular metrics and comparing regular reports helps communicate achievements effectively, demonstrating progress towards sustainability goals.

3. Support certification achievements

Certificates like Cradle to Cradle (C2C) rely on firms measuring circularity to meet high circular economy standards.15 Companies can enhance key areas based on circular transition indicators, making progress towards earning such certifications by evaluating and improving their practices.

4. Assess the legal cost of business practices

With increasing climate change regulations, such as extended producer obligations and plastic taxes, companies must track their circularity to remain compliant. Measuring circularity helps businesses anticipate legal costs and adapt to evolving frameworks, like those introduced by the European Commission, ensuring they meet sustainability requirements.

If you are also interested in ESG reporting metrics, read Types of Metrics CEOs Must Use in ESG Reporting.

Carbon footprint is another metric firms need to assess to see their progress towards net zero. To automate the measurement process you need a carbon footprint calculator. Read Top Carbon Footprint Software/Tools for Businesses if you are interested in the carbon footprint software.

FAQs

How can firms collect data for measuring these metrics?

To accurately measure circular economy metrics, firms may need to collect data from their suppliers. For example, calculating resource productivity requires information on the material composition, such as what percentage of sheet metal is sourced from natural resources versus recycled materials. Cloud-based supply chain ERP systems can facilitate data exchange throughout the supply chain, provided suppliers agree to collaborate.

Additionally, companies can partner with environmental consultancies that specialize in gathering and analyzing data relevant to circular economy practices, offering expert guidance on these processes.

How do you evaluate a circular economy?

Evaluating a circular economy involves using circular economy metrics and circular transition indicators to assess how efficiently resources are utilized, waste generation is minimized, and environmental impacts are reduced. Key metrics include resource efficiency, waste management practices, and the use of recycled materials versus natural resources. Businesses can track progress by monitoring circularity metrics, such as material consumption and resource productivity, to ensure alignment with circular business models.

Data can be collected from supply chains, using methodologies like the European Commission’s circularity framework, which provides consistent guidelines for evaluating progress. Additionally, companies should assess how well they are integrating circular principles into their operations and business case by measuring progress towards established circular economy targets, ensuring compliance with evolving regulatory requirements, and addressing climate change and sustainability goals.

This article was drafted by former AIMultiple industry analyst Görkem Gençer.

External Links

- 1. The Circular Economy Could Unlock $4.5 trillion of Economic Growth, Finds New Book by Accenture.

- 2. H&M And IKEA Want Your Old Stuff Back, Here’s Why.

- 3. Circular Economy From theory to practice. Deloitte. Accessed: September/13/2024.

- 4. The global corporate water footprint. McKinsey & Company. Accessed: September/11/2024.

- 5. GRI - Standards.

- 6. Green Power Partnership Top 30 Retail | US EPA.

- 7. Lifetime Warranty– Waterhaul. Waterhaul

- 8. H&M And IKEA Want Your Old Stuff Back, Here’s Why.

- 9. Digital Offering.

- 10. National Circularity Gap Metric - Circularity Gap Reporting Initiative.

- 11. Circulytics: Measuring circular economy performance.

- 12. Circular Transition Indicators (CTI) | WBCSD. The World Business Council for Sustainable Development

- 13. Voice of the Consumer 2025 | PwC Global .

- 14. Margolis, J. D., Elfenbein, H. A., & Walsh, J. P. (2007). Does it pay to be good? A meta-analysis and redirection of research on the relationship between corporate social and financial performance. Ann Arbor, 1001, 48109–1234.

- 15. Cradle to Cradle Certified® - Cradle to Cradle Products Innovation Institute.

Comments

Your email address will not be published. All fields are required.