Generative AI is becoming a strategic tool for manufacturers facing challenges like supply chain disruptions, labor shortages, and rising cost pressures. It helps automate design, predict maintenance needs, and optimize supply chains, while driving efficiency, reducing costs, and speeding up innovation.

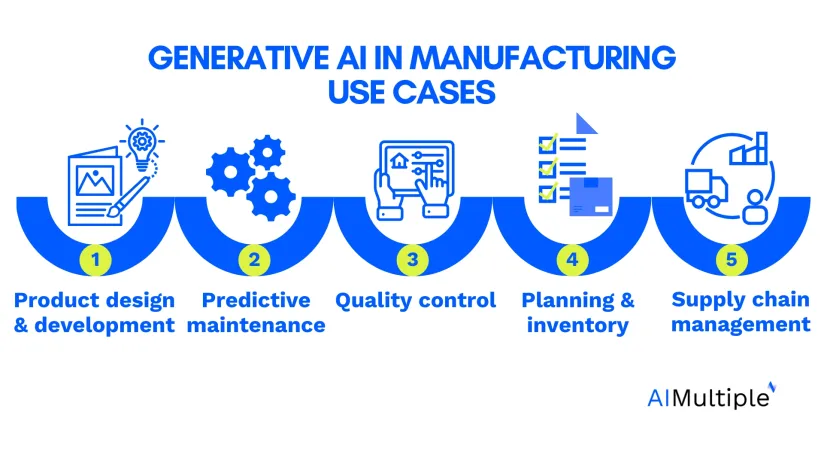

Explore the top 5 use cases, the benefits, and risks of utilizing generative AI in manufacturing.

1. Product design and development

Generative design software can quickly generate a wide range of design options based on the specific constraints and goals you provide.

This helps speed up the design process, reduces development costs, and can lead to more creative and innovative solutions.

2. Predictive maintenance

Manufacturers can predict equipment failures and perform proactive maintenance by leveraging machine learning algorithms. These models are trained using data from the machines, including temperature, vibration, sound, and other relevant parameters.

As the models process this data, they can forecast potential issues, enabling preventative maintenance and minimizing downtime.

3. Quality control

AI can enhance quality control in manufacturing by analyzing images of past products and identifying defects that may have been overlooked. Using this data, generative AI tools can create a model that predicts whether a newly manufactured product is likely to be faulty.

This approach can significantly reduce costs and minimize waste associated with defective products.

4. Production planning and inventory management

Generative AI models can simulate different production scenarios, predict demand, and optimize inventory levels. These models can forecast demand more accurately by analyzing historical customer data. This allows for better production planning and optimal inventory management.

These models can also simulate various scenarios, taking into account factors like demand changes, resource availability, and supply chain dynamics. This enables businesses to make proactive decisions and minimize costs associated with overproduction or stockouts.

5. Supply chain management

Generative AI in supply chain can be used to create optimized supply chain models by factoring in various operations, including costs, delivery times, reliability, and more. This allows businesses to design more efficient and effective supply chains that can adapt to changing conditions.

Also, it can automate supply chain processes such as:

- Supplier risk assessment

- Anomaly detection

- Transportation and routing optimization

5 Benefits of generative AI in manufacturing

The manufacturing industry can achieve greater productivity, innovation, and adaptability, securing a significant competitive advantage in an increasingly complex and dynamic market.

1. Improved efficiency

Generative AI boosts manufacturing operations by automating processes from design and production planning to quality control.

It accelerates production times and improves overall efficiency by identifying bottlenecks and optimizing workflows.

For instance, AI-driven systems can analyze real-time data from production lines to ensure smooth, continuous operations, reducing the need for manual intervention.

2. Cost savings

Generative AI can help reduce costs in the manufacturing process by enhancing predictive maintenance capabilities and minimizing waste.

By leveraging historical data and machine learning algorithms, generative AI can predict machine failures before they occur, thereby minimizing unplanned downtime.

AI-powered quality control systems help reduce the likelihood of defects, resulting in savings on materials, labor, and rework costs. By catching issues early, these systems ensure higher product quality and greater efficiency throughout the manufacturing process.

3. Enhanced innovation

With generative design, AI models can generate and explore thousands of design possibilities within specific constraints, driving creativity and innovation.

This approach often leads to optimized, lightweight, and cost-effective product designs that traditional methods may not be able to achieve. Manufacturers can leverage these AI-driven insights to stay ahead of industry trends and create unique products that meet market demands.

4. Better decision making

Generative AI insights, based on historical sales data, inventory levels, and market trends, enable manufacturers to make informed decisions in areas such as production planning, inventory management, and supply chain optimization.

By identifying patterns and anomalies, AI-driven data analytics enhances strategic planning, ensuring that manufacturing operations align with key business goals.

5. Reduced downtime

Predictive maintenance, powered by generative AI, helps manufacturers anticipate equipment malfunctions before they occur.

By analyzing data from sensors and other sources, AI systems can schedule maintenance during planned downtime, reducing the risk of unexpected breakdowns. This minimizes production disruptions, boosts equipment efficiency, and enhances overall productivity, all while reducing the costs of emergency repairs.

What are the risks of integrating generative AI in manufacturing?

While generative AI offers significant benefits in manufacturing, its implementation also presents several risks. Some of the primary risks associated with generative AI in manufacturing include:

1. Data quality and availability

Generative AI relies heavily on high-quality, relevant data to function effectively. If the data is incomplete, inaccurate, or biased, it can raise ethical concerns about generative AI, leading to flawed insights, poor predictions, or faulty designs.

Additionally, legacy systems in manufacturing may not offer the level of data integration required for AI operations, which could limit the effectiveness of AI-driven processes.

2. Cybersecurity threats

Integrating generative AI into manufacturing processes can increase exposure to cybersecurity risks. Hackers may target AI systems to gain access to sensitive operational data, disrupt production lines, or manipulate AI models, potentially causing errors in manufacturing workflows.

Advanced cybersecurity measures are necessary to protect AI systems from such attacks. This can add complexity and increase the cost of implementation.

3. Cost and complexity of implementation

Deploying generative AI systems typically requires a significant upfront investment in infrastructure, including sensors, advanced computing systems, and integration with existing platforms.

Training AI models and ensuring smooth integration with legacy systems can be complex and time-consuming, often requiring specialized expertise to manage the process effectively.

4. Over-reliance on AI systems

Dependence on generative AI for critical decisions, such as production planning or quality control, could reduce human oversight, potentially leading to issues if the AI produces errors or faces unexpected scenarios outside its training data.

Balancing human intervention with AI-driven automation is essential to mitigate this risk.

5. Job displacement

The automation of tasks traditionally performed by human workers can raise concerns about job displacement, potentially affecting workforce morale and having broader societal impacts.

Retraining programs and workforce adaptation strategies are crucial for mitigating this risk.

Check out AI job loss to learn about job displacement in AI and automation.

6. System failures and unintended outcomes

Generative AI models may produce designs or recommendations that are innovative but impractical, unsafe, or cost-inefficient for actual production.

Errors in AI-driven production processes or supply chain operations could result in financial losses or reputational damage.

7. Lack of interpretability and transparency

Generative AI models, especially those based on advanced machine learning algorithms, are often seen as “black boxes” because their decision-making processes are not always transparent.

This lack of interpretability can make it challenging to trust AI recommendations or diagnose issues when they arise.

8. Supply chain dependencies

AI-driven supply chain optimization systems depend on accurate real-time data from global suppliers. Any disruptions or inaccuracies in this data can cause damage to the system, resulting in suboptimal decisions and inefficiencies.

Over-reliance on predictive analytics for supply chain management can also lead to vulnerability during unexpected events, such as geopolitical disruptions or natural disasters.

What is generative AI in manufacturing?

Generative AI refers to a type of artificial intelligence that focuses on creating new data from the existing data it has been trained on.

By leveraging generative AI, manufacturers can analyze vast amounts of historical data, identify patterns, and generate valuable insights that were previously difficult to obtain through traditional methods.

These insights help improve manufacturing processes, optimize supply chain operations, and enable significant competitive advantages in the evolving manufacturing landscape.

Generative AI has numerous applications across various domains, including natural language processing (NLP), image synthesis, music composition, and drug discovery, among others. It’s also the underlying technology for chatbots like OpenAI’s ChatGPT and GPT-4, which generate human-like text based on the input they receive.

Generative AI systems also contribute to quality control and product design. By utilizing data analysis and advanced algorithms, these systems can develop innovative solutions to enhance product quality while achieving cost savings.

Integrating AI into existing systems, including legacy systems, enables manufacturing sector professionals to optimize processes, enhance production efficiency, and gain real-time data analysis capabilities. This allows for process improvement that aligns with key performance indicators and ensures data privacy when utilizing relevant data sources.

Comments

Your email address will not be published. All fields are required.