Leverage Value Stream Mapping to Maximize Value in '24

As the lean approach suggests, focusing on customer value and minimizing waste helps businesses improve their processes. Value stream mapping is one of the fundamental methods of lean that visualizes processes to give a better understanding. It is an easily applicable tool and can be implemented in any process. With the latest process mining tools, businesses can take advantage of process mining to quickly generate their value stream maps.

What is value stream mapping?

Value stream mapping is a visual planning tool that is widely used in the lean approach. It shows all steps in a specific process and evaluates the time taken at each stage. It allows businesses to have a full understanding of how processes work and helps them make improvements in terms of clarity and efficiency.

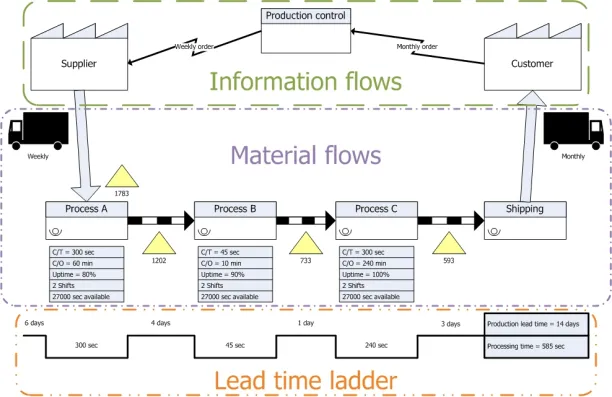

A value stream map consists of three main parts: information flow, material flow, and time ladder. Besides relevant data, businesses use standardized symbols representing items and processes to fill these parts. Below is an example of what a value stream map looks like.

To understand value stream mapping better, here is how each part of the value stream map works.

Information flow

This part shows how the required information for processes flows in the value stream map. In processes, there might be communication problems about how the information flows, and companies can discover those by analyzing information flows.

Material flow

Material flow shows the route of the product/service including each step in the process. This part includes data about each step like inventory levels, cycle times, and uptime. Besides, companies can see their shipment method and the frequency of delivery and supply orders in the material flow. This part helps businesses to identify wastes and focus on the value-adding steps in processes.

Time ladder

Businesses can observe the duration of each step and how long it takes from one step to another. From the time ladder, businesses can see what percentage of their processes are value-adding and how much time they waste between different steps.

Why is it important?

Value stream mapping helps businesses improve their processes and analyze their processes from a value perspective. From the insights gained from this tool, companies can take accurate actions to solve their problems and improve their process efficiency. Using a value stream map is essential for businesses to:

Understand complex processes

The increasing complexity of processes and their excessive deviation from the ideal ones limits businesses from developing effective solutions for process improvement. While it is harder to understand as-is processes, discovering their as-is processes is critical for companies. With value stream mapping, companies can visualize their processes and identify the root causes of bottlenecks. This enables them to have full control of processes and a better understanding of what is happening.

Implement the lean approach successfully

As indicated in our process improvement article, there are different process improvement approaches for companies to increase their efficiency. While each methodology may impact businesses depending on the process scope, lean is one of the leading strategies that focuses on customer value. Value stream mapping is fundamental to implementing the lean approach successfully. With this tool, businesses can identify the root cause of waste and eliminate them to improve customer value. Considering today’s competitive environment, value stream mapping is an easy-to-use and effective tool to increase the quality of the product and enhance process efficiency.

How to draw a value stream map?

Drawing a value stream map helps businesses focus on value-adding steps and eliminate waste by visualizing their processes from the input of raw materials to the delivery of final products or services. We have not come across products that allow users to create a value stream map however, as mentioned later, process mining tools can provide the most relevant information to create such maps.

Companies can understand the strengths/weaknesses of their processes with a value stream map by following these steps:

Choose which processes to focus on

While some companies decide to map their entire value chain to have a better idea of their whole processes, some focus on specific processes to get rid of complexity and go into details in those particular processes.

Define the steps

After choosing the process to map, now it is time to identify the steps from the start to the end.

Draw the information flow

Information flow is how businesses gain the information needed to generate their output. For example, customers have a certain level of demand for cars, and the car manufacturing company needs to order a particular number of components from suppliers. It can use this information to plan a weekly or monthly schedule for its manufacturing process.

Collect and add data to the map

Businesses require data to create a timeline of their processes and understand how efficiently process steps work. Here are several examples of data that might be needed:

- Inventory levels

- Cycle time

- Transfer time

- Amount of workforce

- Batch size

After generating timelines, companies can now see how long their processes take and how much of the process is value-adding.

Identify non-value-adding steps and eliminate them

From the value stream map, companies identify the non-value-adding steps and eliminate them to reduce their costs. These steps are called waste in the lean approach. Below are the main seven types of waste that might cause unnecessary costs in businesses.

- Transportation: Businesses should see if they can shorten the time taken to transport products, services, or information from one step to another.

- Waiting time: Bottlenecks spoil the continuity of processes and cause previous steps to stop. By solving these bottlenecks, businesses can eliminate the waiting time.

- Excessive inventory: High inventory levels cause high inventory costs. Companies should optimize inventory levels to eliminate unnecessary costs.

- Overproduction: Even if companies don’t sell perishable products, overproduction will have additional costs for storing until a customer buys the product.

- Over-processing: Companies can see if they can meet acceptable conditions for the output with fewer resources to reduce their costs.

- Defects: Companies should fix the steps where defective products are manufactured as reworking or scrapping them is costly.

- Unnecessary motion: If the workplace isn’t optimized, workers will need more time to reach different spots to fully perform their tasks. Businesses can shorten several steps by reducing this motion.

Repeat the whole procedure until reaching the “perfect” value stream map

After eliminating non-value-adding steps, businesses can re-create their value stream maps to observe their impact. This newly created map is called the “future state value stream map.”

Afterward, companies can continue to reduce waste even further until they reach “perfect” processes where there is no waste left in the process.

What are the main benefits?

Using value stream mapping enables businesses to visualize how their processes work, monitor performance, and identify wastes to reduce unnecessary costs. When companies use this tool properly, they can achieve the following benefits and improve their processes.

Increased efficiency

As value stream mapping helps identify wastes and bottlenecks, businesses can eliminate unnecessary costs and reduce waiting times to make their processes more efficient. As a result, they can manage their processes with fewer resources.

Higher end-product quality

Value stream mapping helps companies focus on value-adding steps and find ways to improve them. As they work on increasing customer value, it impacts higher quality and customer satisfaction improves. For example, a process mining case study claims that Patria Land Systems has reduced rework in its order-to-cash processes and increased customer satisfaction.

Better decision-making

By visualizing processes, businesses can have a full understanding of their as-is processes. This enables companies to make accurate decisions based on their actual position.

Improved collaboration between different teams

Different teams can work in different steps under processes. Value stream mapping shows how different teams affect each other and allows businesses to focus on having a smooth workflow by increasing collaboration.

What are several applications?

Manufacturing

Manufacturing is where the lean approach started. By analyzing the steps in manufacturing processes with value stream mapping, companies can eliminate waste and use their resources more efficiently.

Logistics

Value stream maps can be used to identify the root causes of delays and wastes in logistics processes. This can be achieved by detecting old inventory items, insufficient employee competencies, and a lack of storage capacity.

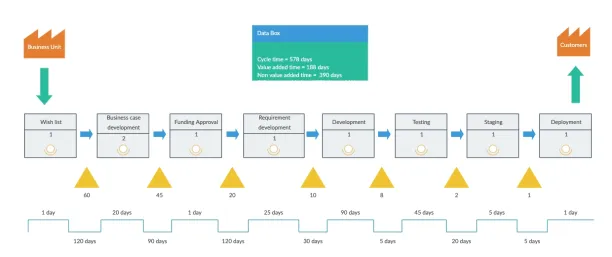

Software Development

This tool is also popular in software development processes which starts from the idea and ends in the deployment step. The idea is to reduce wait times and the need for rework during this process. Below is an example value stream map for software development.

Healthcare

Value stream mapping can be used in healthcare to improve the quality of patient treatment most effectively. For example, an orthopedic hospital in India has applied this tool to improve its productivity. By reallocating the workspace and identifying bottlenecks, the hospital reduced the waiting time for patients by 5 minutes and increased patient intake from 45 to 62 per shift.

How does the latest technology impact value stream mapping?

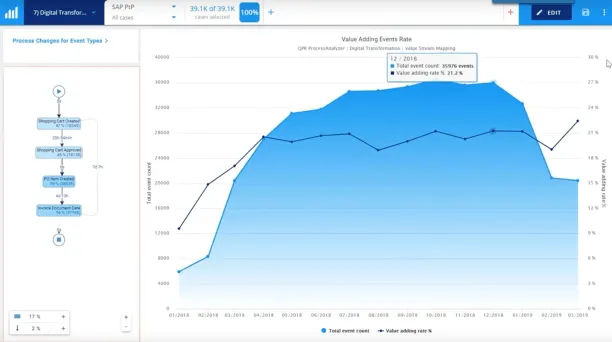

Process mining solutions help businesses to create value stream maps. These help visualize all value-adding steps of a process from start to end. As seen below, this technology also provides value-adding events rates in real-time to track business performance.

By visualizing processes and gathering relevant data, businesses can see their “as-is” processes and understand their strengths/weaknesses. With these insights, they can identify bottlenecks and focus on eliminating waste for process improvement.

Feel free to read our in-depth process mining guide, if you want to learn more about this technology.

These articles can also interest you:

- Lean Process Improvement: In-depth Guide for Your Business

- Process Improvement: In-depth Guide for Businesses

- Process Discovery: First Step to Understand Processes

If you still have questions about value stream mapping, we would like to help:

Cem has been the principal analyst at AIMultiple since 2017. AIMultiple informs hundreds of thousands of businesses (as per similarWeb) including 60% of Fortune 500 every month.

Cem's work has been cited by leading global publications including Business Insider, Forbes, Washington Post, global firms like Deloitte, HPE, NGOs like World Economic Forum and supranational organizations like European Commission. You can see more reputable companies and media that referenced AIMultiple.

Throughout his career, Cem served as a tech consultant, tech buyer and tech entrepreneur. He advised businesses on their enterprise software, automation, cloud, AI / ML and other technology related decisions at McKinsey & Company and Altman Solon for more than a decade. He also published a McKinsey report on digitalization.

He led technology strategy and procurement of a telco while reporting to the CEO. He has also led commercial growth of deep tech company Hypatos that reached a 7 digit annual recurring revenue and a 9 digit valuation from 0 within 2 years. Cem's work in Hypatos was covered by leading technology publications like TechCrunch and Business Insider.

Cem regularly speaks at international technology conferences. He graduated from Bogazici University as a computer engineer and holds an MBA from Columbia Business School.

To stay up-to-date on B2B tech & accelerate your enterprise:

Follow on

Comments

Your email address will not be published. All fields are required.