Enterprise batch scheduling software can automate tasks that take up almost of half internal IT team’s effort. However, there are tens of solutions with different costs. For:

- SMEs & midmarket companies: All batch schedulers can satisfy your requirements so we recommend focusing on ease of use, pricing and deployment options. Finally, solution should provide integrations to your most commonly used systems like ERP.

- Enterprises: Integrations and security are key. You can also see enterprise job scheduling tools which only includes solutions with extensive integrations and enterprise-grade data security.

Batch scheduling market leaders

Here is a list of selected leading batch job scheduling tools listed based on their score except for the sponsors which are prioritized in the list:

| Vendors | Rating* | Capabilities** | Free trial | # of employees |

|---|---|---|---|---|

| ActiveBatch | 4.4 based on 251 reviews | Comprehensive | ✅ | 533 |

| RunMyJobs by Redwood | 4.8 based on 140 reviews | Comprehensive | ✅ | 533 |

| Stonebranch | 4.8 based on 79 reviews | Comprehensive | ✅ | 152 |

| Fortra's JAMS | 4.7 based on 142 reviews | Comprehensive | ✅ | 1,721 |

| BMC Control-M | 4.7 based on 150 reviews | Comprehensive | ✅ | 9,941 |

| AWS Batch | 4.4 based on 86 reviews | Comprehensive | ✅ | 130,371 |

| Tidal by Redwood | 4.8 based on 50 reviews | Comprehensive | ✅ | 533 |

| AutoSys by Broadcom | 4.5 based on 44 reviews | Comprehensive | ❌ | 13,212 |

| Azure Batch | 4.1 based on 22 reviews | Limited | ✅ | 244,900 |

| VisualCron | 4.7 based on 18 reviews | Limited | ✅ | 1 |

| Activeeon ProActive | 4.5 based on 3 reviews | Limited | ✅ | 24 |

*Ratings are based on reviews on B2B user review platforms, such as Gartner and G2.

**Basic batch schedulers typically lack the advanced features found in specialized job scheduling or workflow automation tools. These batch schedulers may also operate in limited environments and struggle with external system integration.

Which batch scheduling features do market leaders provide?

After preparing their shortlists, buyers should evaluate companies based on workload, objectives, goals, and key features their business require, such as deployment environment or integration capabilities:

| Vendors | Deployment | ERP Integrations | Data Platform Integrations |

|---|---|---|---|

| ActiveBatch | On-prem, Public cloud | MS Dynamics, Oracle PeopleSoft, SAP BusinessObjects, SAP NetWeaver | Informatica Cloud, Informatica PowerCenter |

| RunMyJobsby Redwood | On-prem, Public cloud, SaaS | Oracle PeopleSoft, Oracle JDE EnterpriseOne, SAP BusinessObjects, SAP BW, SAP CPI-DS, SAP Datasphere, SAP ERP S/4HANA, SAP IBP, SAP Industry Solutions, SAP Integration Suite | Databricks, Informatica Cloud, Snowflake |

| Stonebranch | On-prem, Public cloud, SaaS | Oracle PeopleSoft, SAP BusinessObjects, SAP ERP S/4HANA, SAP IBP, SAP NetWeaver | Databricks, Informatica Cloud, Informatica PowerCenter, Snowflake |

| Fortra's JAMS | On-prem, Public cloud | Oracle JDE EnterpriseOne | Informatica Cloud, Informatica PowerCenter, Snowflake |

| BMC Software Control-M | On-prem, Public cloud | MS Dynamics | Databricks, Informatica Cloud, Snowflake |

| AWS Batch | Cloud | SAP ERP S/4HANA | Informatica PowerCenter Snowflake |

| Tidal by Redwood | On-prem | Oracle PeopleSoft, Oracle JDE EnterpriseOne | Informatica Cloud,Informatica PowerCenter |

| AutoSys by Broadcom | On-prem, Public cloud | SAP Industry Solutions, SAP NetWeaver | Databricks |

| Azure Batch | Cloud | SAP NetWeaver | Informatica PowerCenter Snowflake |

| Visualcron | On-premises | - | Informatica |

Shortlisted batch scheduling tools

Statements in the pros and cons sections are based on B2B review platforms such as TrustRadius, G2, and Capterra.

Here is a detailed analysis for top 10 batch scheduling tools:

1. ActiveBatch

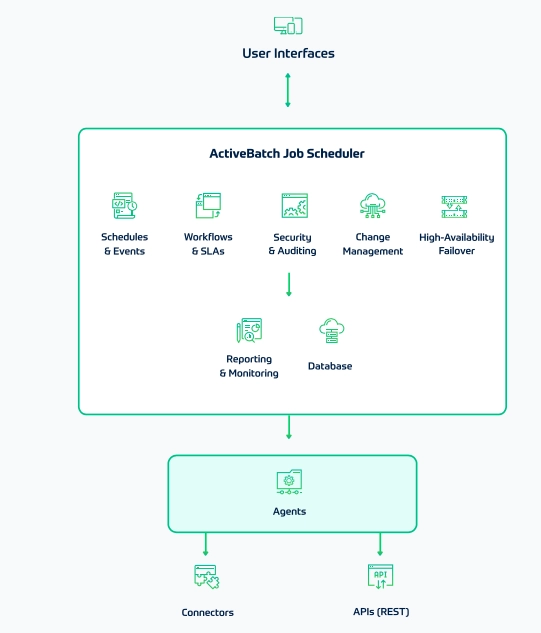

ActiveBatch is an enterprise job scheduling and workload automation solution that offers:

- Advanced Flow Control Job Steps, like ForEachRow and If-Branch, to manage complex scheduling workflows with

- Drag-and-drop workflow creation

- Beyond basic If-Else statements to control execution flow.

- An integrated content library with production-ready job steps

- Connectors for popular platforms, pre-built actions, and lifecycle management for scripts.

This capability improves batch job scheduling by simplifying setup, ensuring seamless integration, and maintaining script integrity. Check out how ActiveBatch workload automation and batch scheduling works:

Pros:

- Scheduling: ActiveBatch serves as a centralized system to schedule jobs across the enterprise thanks to its off-the-shelf integrations, Super REST API adapter for integrating to internal services and agents that can orchestrate on-prem environments. Our observations of its job scheduling functionality is also supported by other users: It scores 9.5 out of 10 across 80 user reviews on G2.

- Ease of use: Users frequently commend ActiveBatch for its user-friendly and intuitive interface. In fact, 16% of all ActiveBatch reviews pulled from B2B review platforms consider the tool easy to use.

- Integrations: ActiveBatch receives high marks for its integration capabilities, allowing connection with popular apps and scripts such as PS1, BAT, and CMD. G2 reviewers, for example, rate ActiveBatch’s integration capabilities at 9.1

- Additional capabilities: ActiveBatch users rate additional capabilities above average on Trustradius, with alerts and notifications scoring 9.3, analysis and visualization 9.6, and error logging 9.4

Cons:

- Learning curve: The software may present a steeper learning curve, particularly for complex workflows and advanced features, according to user reviews on G2 and Trustradius.

Learn more about ActiveBatch features, pros and cons.

2. RunMyJobs by Redwood

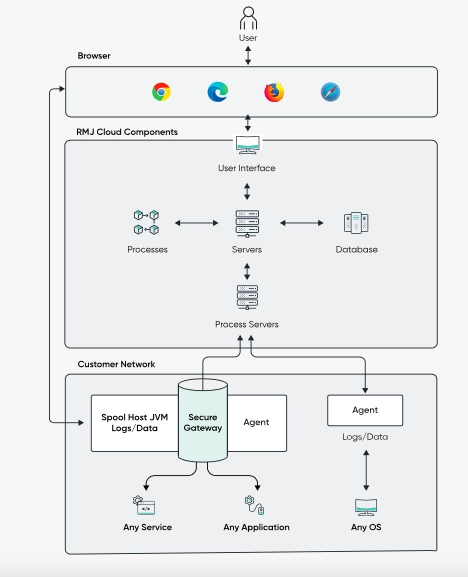

RunMyJobs can be useful for batch scheduling since it provides:

- Object-oriented programming (OOP), which simplifies code maintenance, streamlining complex task scheduling and change handling.

- The most SAP module integrations, including S/4HANA, BTP, SAP Industry Solutions and more, offering out-of-the-box SAP wizards and 1000+ SAP job templates.

- Automated and easy to set-up load balancing configurable in a cloud-based environment, ensuring consistent performance and high availability during peak loads or disruptions.

- AI Assistant, which leverages integrated ServiceNow and ChatGPT in the SAP workflow. ChatGPT evaluates message urgency, and if needed, triggers automatic ServiceNow ticket creation, pausing downstream steps until resolution.

See how Redwood can create a simple process automatically:

Pros:

- Jobs scheduling: On G2, Redwood has the highest score for jobs scheduling features with 9.8 out of 59 reviews.

- Multi-platform scheduling: On Trustradius, Redwood RunMyJobs has the highest score for the ability of managing an entire process across various platforms with 9.6

- Additional capabilities: Redwood receives high ratings for additional capabilities: 9.4 for alerting and notifications, 9.4 for logging, and 9.6 for analysis and visualization.

Cons:

- Format issues: A major problem reported by users on PeerSpot is the limited format options for reports and data files.

Learn more about RunMyJobs and compare it against its alternatives better.

3. Stonebranch UAC (Universal Automation Center)

Stonebranch provides Universal Automation Center (UAC) offers:

- workflow management capability across various systems and business apps, irrespective of data location.

- Easy-to-use drag-and-drop interface to design workflows.

Pros:

- Integration: Stonebranch batch scheduling offers integrations with diverse systems and applications. On G2, reviewers rate its app integrationss as 9.0 and API integration 8.9.

- User friendliness: According to Stonebranch reviews gathered from B2B review platforms, 2% highlight its ease of installation, and 3% emphasize its user-friendly interface.

Cons:

- Analytics and visualization: Some reviewers on PeerSpot have requested improvements to the analytics and reporting features.

Discover top Stonebranch alternatives to assess pros and cons of each tool against each other.

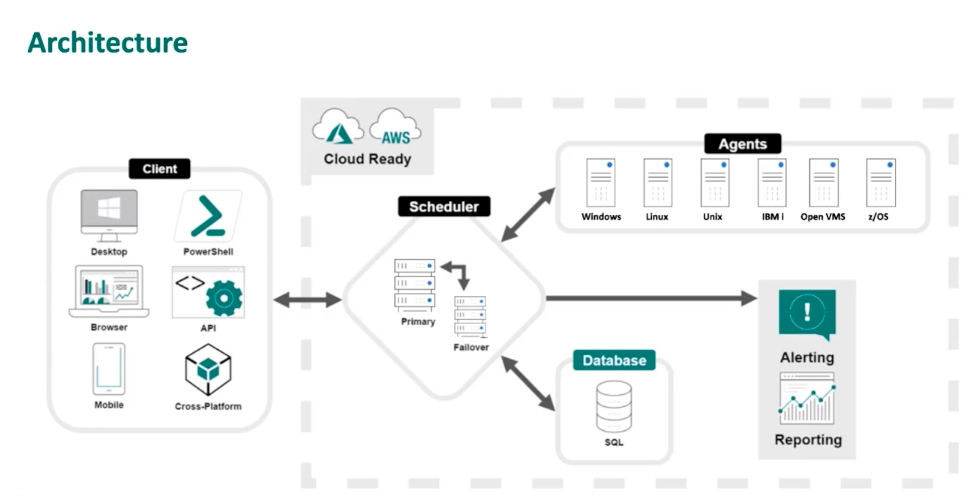

4. Fortra JAMS

Fortra’s JAMS delivers:

- Time-driven, event-driven and conditional job scheduling features

- Centralized job monitoring with notifications for success or failure of workflows.

- Job scheduling: JAMS users on G2 rate jobs scheduling features at 9.4.

- Alerts & logging: JAMS users can set alerts and run logging to ensure regulatory compliance, though these features do not score higher than 8 compared to JAMS alternatives.

- Support: In B2B reviews, 7% of Fortra’s JAMS users positively mention the support team, and 3% specifically highlight the customer support.

Cons:

- Access to server: Most users on PeerSpot reported connectivity issues with the JAMS server when accessed via browser.

Explore more on Fortra’s Jams by checking out our data-driven article on Jams Scheduler. For more details, such as alert setting and logging features, check out Fortra’s Jams Scheduler.

5. BMC Control-M

Control-M by BMC Software is designed to orchestrate enterprise-level workflows and automate batch processing across complex IT environments.

Pros:

- Ease of Use: 15% of all Control-M users rate the tool as easy to use.

- Integration: Control-M receives a high score for application integration, with 9.5 out of 48 reviews on TrustRadius

- Monitoring: 49 Control-M users rate monitoring capability, which includes a comprehensive dashboard for tracking performance and predictions, as 10 on Trustradius.

- Additional capabilities: Users on Trustradius confirm that Control-M batch scheduling offers workflow management, proactive workflow, and error alerts.

Cons:

- Ease of use and set-up: Some users mention that the tool can be complicated to adopt initially, requiring dedicated administration and training. On G2, the tool scores 8.8 for ease of use and 8.4 for ease of setup.

- Clunkiness of interface: In all B2B reviews of Control-M, 2% of users describe the tool as clunky.

Explore competing Control-M alternatives that may better fit your needs.

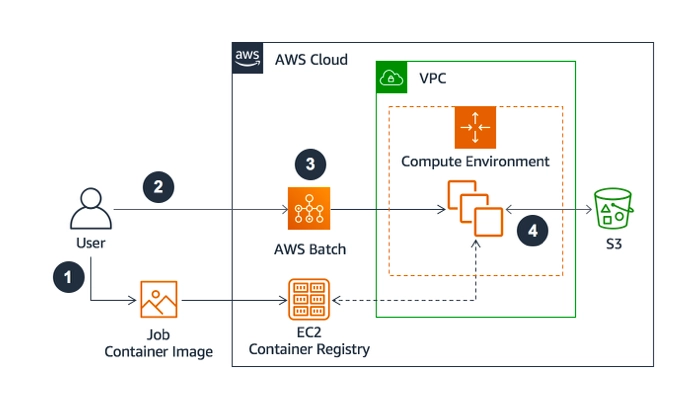

6. AWS Batch

AWS Batch is a batch management tool that can plan, schedule, and execute batch computing workloads.

Pros:

- Scalability: Users on G2 highlight AWS Batch’s capability to run millions of jobs simultaneously without data loss.

Cons:

- Limitations: AWS Batch is constrained to the AWS environment, which means users relying on different cloud services may not find it beneficial.

- Analysis & visualization: Unlike other additional features, AWS Batch users on TrustRadius do not rate its analysis and visualization capabilities favorably.

7. Tidal

Tidal’s batch scheduling software delivers:

- Integrated resource management to optimize resources across various systems and environments.

- Configurable dashboard to monitor and manage batch jobs and processes.

- Job dependency management across applications.

Pros:

- Ease of use: Tidal users on G2 rate the ease of use of the tool as 9.3.

- Multi-platform scheduling: Tidal allows users to integrate with various applications and manage their processes entirely across these systems.

Cons:

- Analysis & visualizations: Users on PeerSpot recommend improvements to the graphical interface and statistical reporting.

Deep dive into Tidal software by covering its pros and cons, features and alternatives.

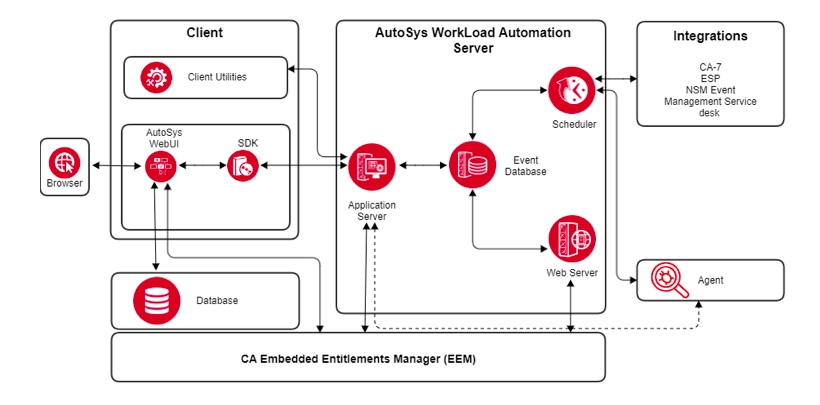

8. AutoSys Workload Automation

AutoSys is a WLA tool that can be applied to schedule batches, manage complex workflows, and trigger tasks.

Pros:

- Ease of use: On G2, AutoSys scores 8.9 for ease of use. Also, 6 out of 10 reviews on PeerSpot mention that the tool has an intuitive interface and user-friendly setup.

Cons:

- Quality of Support: Community support and technical service for AutoSys are rated 8.3, which is below average compared to other Workload Automation (WLA) tools on G2.

Explore more on AutoSys and its alternatives.

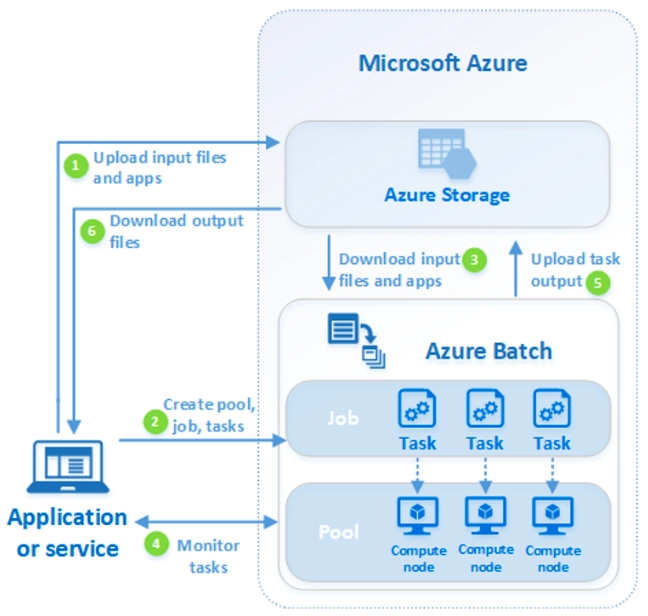

9. Azure Batch

Azure Batch enables the execution of large-scale parallel computing tasks in the cloud, making it ideal for HPC workloads.

Pros:

- Scalability: According to G2 reviews, Azure Batch allows users to frequently run a variety of tasks and process job batches in parallel.

Cons:

- Ease of use: On G2, Azure Batch scores below average at 7.9 out of 10 for ease of use, compared to the average of 9.1 for similar tools.

- Limited environment: While Azure Batch’s native integration with Azure platform apps and services can be advantageous for Azure users, it limits its appeal to users not already invested in the Azure ecosystem.

Learn how to use azure scheduler for batch and job scheduling, and what are its top alternatives.

10. Visualcron

VisualCron is a Windows-based automation platform that enables:

- Support task scheduling, batch/exe execution, MFT (Managed File Transfer) and ETL (Extract, Transform, Load).

- Provide an alert system to sent notifications to users regarding errors and delays

Pros:

- Visualizations: Visualcron users on PeerSpot praise the tool for its intuitive and rich visualizations, which enhance analysis and reporting capabilities.

Cons:

- Ease of use: Visualcron has the lowest ease of use score among all batch scheduling software on G2, scoring 8 out of 10.

Compare Visualcron alternatives and cron alternative to explore the tool better.

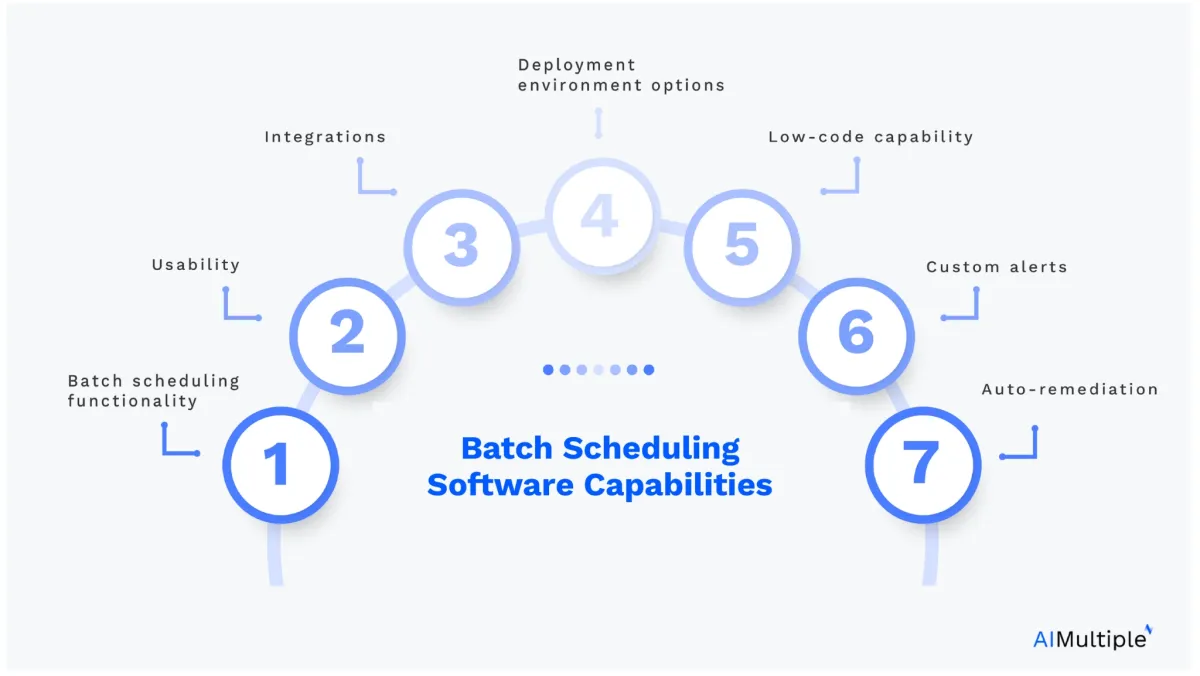

5 Core capabilities for batch scheduling software benchmarking

1- Batch scheduling functionality

Event-based scheduling

Event-based scheduling, also known as event triggering or event driven process automation, is the capability to initiate batch jobs by specific conditions automatically. These events can result from software applications, databases, or other IT systems.

For example, batch scheduling tools can perform file processing once a certain file is dropped into a particular directory.

Event triggering capability can improve efficiency and effectiveness by:

- Reducing manual intervention

- Saving time for higher-value tasks

- Minimizing errors resulting from manual interventions

- Responding to changing business conditions in time.

Constraints-based scheduling

Constraints are requirements that a batch scheduler must consider to schedule and execute batch processes. The main constraints include:

- Resource availability: This constraint ensures that the software schedules manual tasks when the necessary resources are available. For instance, servers must be available to run errands.

- Job and task dependencies: This constraint ensures that batch scheduling software executes the subsequent task if the primary task is completed so that it satisfies dependencies and follows the correct order in the entire batch job. It is an essential aspect of the batch scheduler as 50% of batch tasks are found to be dependent.

Date/time scheduling

Date/time scheduling is the feature allowing users to set time-related details for executing tasks. With this capability, users can specify the start and end date, frequency, and time allocated for the processing. Also, the date and time scheduling feature can include features such as daylight saving time and setting different time zones.

This feature ensures consistency and increases operational efficiency by providing an automated and predictable task execution.

Load balancing

This feature allows the batch scheduler to distribute large volumes of batch jobs and data across different servers based on how busy they are. As a result, load balancing capability can improve performance and efficiency by:

- Optimizing resource utilization

- Increasing processing speed

- Improving scalability.

2. Usability

Monitoring batch tasks

Best batch scheduling tools offer real-time monitoring capabilities to increase visibility over batch processing of tasks and enable employees to identify issues when they occur. This way, businesses can reduce downtime and any other errors.

Real-time monitoring for any batch processing system typically includes features such as:

- Task status tracking: This feature shows the status of each task, whether it is running, completed, or failed.

- Performance monitoring: With this feature, administrators can evaluate the performance of the batching process. For instance, they can estimate how long they take to complete and how many system resources they consume.

- Alerts and notifications: Some tools offer real-time monitoring systems that alert relevant parties if they encounter an error.

Resource management

Resource management allows batch scheduling software to manage and allocate resources such as storage and applications to optimize effective and efficient task execution.

Effective resource management often depends on ERP systems that unify key business functions like HR, finance, and inventory through:

- Monitoring by monitoring resource usage and performance metrics.

- Allocation by assigning specific resources based on constraints such as requirements or resource availability.

- Optimization by monitoring resource utilization, identifying bottlenecks, and dynamically adjusting resource allocation.

- Balancing by constantly assigning resource usage across the system.

3. Integrations

ERP Integrations

Organizations heavily rely on Enterprise Resource Planning (ERP) systems to manage their business processes, such as accounting, human resources or inventory management. Batch scheduling software must integrate with ERP systems to access the recorded data, such as customer orders, and use this data to schedule and execute tasks in batches.

For example, batch job scheduling software integrated into ERP can generate a purchase order if inventory levels fall under a certain threshold set by users. With such integration, batch scheduling tools ensure accurate and consistent data exchange, reduced risks for errors, and improved efficiency and scalability due to automation.

API integration

API integration allows batch-scheduling software to integrate with other software systems, databases, and applications through Application Programming Interfaces (APIs). For example, batch scheduling software can extract data from a database, process this data, and then load it back into the database by using APIs.

API integration capability automates data and service exchange between different software, which can:

- Reduce manual efforts and errors

- Ensure consistency and accuracy.

4. Deployment environment options

There are generally three main deployment environment options provided by vendors to install and use batch scheduling software:

- On-premises environments: The batch scheduling software is installed and runs on servers and hardware within the organization’s data center.

- Cloud environments: With this option, the batch scheduling software is hosted and run in a cloud environment. Examples: AWS Batch or Alibaba Batch Compute

- Hybrid environments: This option combines both on-premises and cloud deployments. Examples: ActiveBatch, Redwood RunMyJobs or Control-M

Learn more details about deployment options for automation tools, such as multi-cloud vs. hybrid-cloud.

5. Low-code capability

Low-code capability enables batch-scheduling software users to perform tasks with minimal programming skills. A low-code tool offers a visual drag-and-drop feature, user friendly workflow interface, pre-built components, and other easy-to-use tools to design and customize batch-scheduling software. The market leaders we listed at the top offer low-code batch scheduling solutions.

What are other capabilities batch scheduling tools offer?

Market leaders stand out by offering other capabilities that reduce human intervention to batch scheduling activities, such as:

Custom alerts

Custom alerts capacity to configure and notify users about specific incidents and conditions. Doing so improves system performance and reduces the risk of potential issues. Some of the incidents or conditions custom alerts can be applied includes:

- Job-status changes: Users can configure alerts to notify them when a job status changes, such as when a job is submitted, starts or completes processing, or fails.

- Job failures: Users can receive alerts when a job fails to complete successfully, allowing them to take immediate action to resolve the issue.

- Resource availability: Alerts can be configured to monitor resource availability, such as when a server or database becomes unavailable or reaches capacity limits.

- Job delays: Users can receive alerts when a task is delayed or takes longer than expected, allowing them to take corrective action to minimize the impact on other assignments or processes.

- System performance: Alerts can be configured to monitor system performance metrics such as CPU and memory usage, disk I/O, or network latency, allowing users to identify potential issues and optimize system performance.

Auto-remediation

Auto-remediation is the software’s ability to identify and resolve issues by implementing corrective actions and verifying the resolution. Auto-remediation reduces manual intervention and ensures system availability. This capability can be achieved if batch scheduling software can:

- Constantly monitor to detect issues

- Send notifications to relevant users

- Analyze the problems to understand the root cause behind them.

How did we choose the market leaders?

Batch scheduling tool providers include workload automation tools, enterprise job scheduling software, and vendors specifically focusing on batch scheduling solutions.

- The variety of categories (WLA, job scheduling, batch scheduling) that can schedule batch tasks

- Numerous vendors

- The high number of batch-scheduling use cases against which vendors can be evaluated

- Migration difficulties since most companies already have batch scheduling systems in place.

We shortlist the following vendors based on these 3 parameters:

- Number of employees on LinkedIn, focusing on the companies with higher employees

- Focus, including all vendors that claim to offer batch scheduling solutions on their websites.

- Market leadership, selecting vendors with the highest number of reviews on different B2B review platforms.

Check out AIMultiple’s data-driven and comprehensive lists for more:

- Batch scheduling software

- WLA tools

- Enterprise job scheduler

- IT automation software

- Windows job scheduling software

- SAP job scheduling software

FAQ

What is batch scheduling software?

Batch scheduling software allows users to automate processes that run without manual intervention. These tools can schedule and execute routine tasks, such as file transfers or data processing.

Enterprise-level batch schedulers often include features like event-based automation, date/time scheduling, and offer robust monitoring and integration capabilities.

What is the difference between batch scheduling software and job scheduling software?

Batch scheduling involves scheduling a specific group of jobs to run during designated batch windows, typically during low-resource periods such as overnight.

In contrast, enterprise job scheduling software provides broader automation capabilities, enabling cross-platform scheduling and management of automated processes.

What are the benefits of batch scheduling?

Enterprise batch scheduling addresses the growing complexity of IT operations as digital initiatives expand and workloads increase across hybrid and multi-cloud environments. These tools streamline batch processing by eliminating manual intervention, reducing the risk of human error, and providing flexibility to adapt to changing needs.

Key benefits for IT teams include:

– Enhanced reliability, improving SLAs and providing peace of mind

– Simplified troubleshooting with centralized log repositories

– Comprehensive visibility and reporting across diverse environments

– Seamless integration with any endpoint, application, or vendor

– Optimized resource utilization through load balancing and automated server provisioning

– Reduction of manual tasks, minimizing delays and errors

– Increased capacity for IT teams to focus on high-value projects

What is a batch job?

A batch job automates repetitive tasks and optimizes system resource usage. These jobs consist of grouped tasks executed in sequence within a batch processing environment, without user intervention. Batch jobs can include tasks like data entry, report generation, database maintenance, and backups, typically running during off-peak hours to minimize system impact.

What is SOAP?

SOAPs, service orchestration and automation platforms, enhance workload automation by enabling workflow orchestration and resource planning. By implementing SOAPs, organizations can streamline business processes, fostering agility.

IT automation trends show that 80% of enterprises will adopt SOAPs by 2024, to effectively manage cloud-based workloads.

Compare SOAPs through our up-to-date and objective lists.

SOAP vs. Batch Scheduling software

SOAP emphasizes real-time orchestration and flexibility while batch scheduling is more about executing set tasks on a schedule. Organizations may choose SOAP for dynamic environments and batch scheduling for routine, predictable workloads.

Here are more details:

SOAPs

– Functionality: Provides workflow orchestration and resource planning across hybrid infrastructures, enabling real-time process management.

– Flexibility: Supports dynamic workflows and can adapt to changes quickly, enhancing organizational agility.

– Integration: Works well with cloud-based workloads and can integrate various services and applications.

– Use Cases: Ideal for complex, interactive processes requiring real-time data exchange.

Batch Scheduling

-Functionality: Executes predefined jobs or tasks at scheduled times, often without real-time user interaction.

– Flexibility: Less adaptable to changes; typically runs on fixed schedules, making it less agile.

– Integration: Focuses on executing jobs that may not require constant connectivity, often used for large data processing tasks.

– Use Cases: Suitable for regular data processing tasks, such as overnight data loads or report generation.

What is Batch Job Scheduling and How is it Different from Batch Scheduling?

Batch job scheduling is the process of automating and managing the execution of non-interactive tasks (batch jobs) at set times or in response to events. It ensures jobs run in the right order, at the right time, and with proper resource allocation.

While “batch scheduling” is often used interchangeably, it typically refers to the broader concept of planning and timing grouped tasks. In contrast, “batch job scheduling” emphasizes the automation of specific executable jobs.

It’s critical for efficiency in IT operations, ensuring smooth processing of large data volumes without manual intervention.

Transparency statement

AIMultiple serves numerous technology vendors, including Stonebranch Redwood which provides Active Batch, RunMyJobs, and Tidal.

Further reading

Learn more on batch processing systems and batch automation:

External links

- 1. ActiveBatch | ActiveBatch Workload Automation.

- 2. Redwood RunMyJobs Workload Automation | Redwood.

- 3. JAMS Workload Automation | Fortra. Fortra's JAMS Enterprise Job Scheduler

- 4. High Performance Computing Lens.

- 5. AutoSys Architecture. CA INC

- 6. Azure Batch runs large parallel jobs in the cloud - Azure Batch | Microsoft Learn.

Comments

Your email address will not be published. All fields are required.