Manufacturing AI solutions can lower maintenance costs and customize product designs. After reviewing over 50 manufacturing AI tools, we identified the top options in the market.

| Manufacturing AI software Manufacturing AI solutions from each category based on their company size | Best for | |

|---|---|---|

1. | End-to-end cloud-based manufacturing management | |

2. | AI-powered optimization for manufacturing processes | |

3. | AI-driven predictive maintenance for industrial assets | |

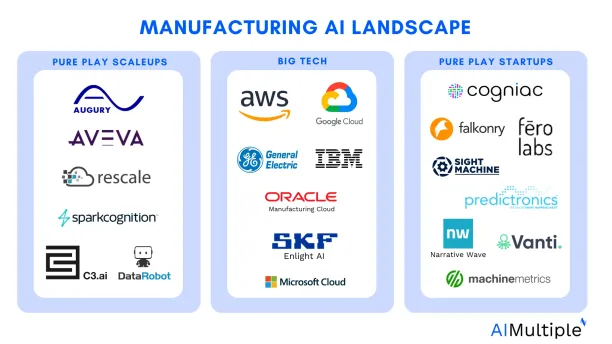

Explore and compare the top manufacturing AI solutions within each relevant category to select the most suitable tool for your needs:

Selecting top 20 manufacturing AI software

| Tools | Types | # of employees | Year founded |

|---|---|---|---|

| AWS | Big Tech | 100-500k | 2006 |

| General Electrics | Big Tech | 100-500k | 1892 |

| Google Cloud AI in Manufacturing | Big Tech | 100-500k | 2008 |

| IBM Watson for Manufacturing | Big Tech | 100-500k | 1911 |

| Microsoft Azure AI for Manufacturing | Big Tech | 100-500k | 1975 |

| SKF Group | Big Tech | 100-500k | 1907 |

| Oracle Manufacturing Cloud | Big Tech | 100-500k | 1977 |

| Augury | Scaleups | 100-500 | 2011 |

| Aveva | Scaleups | 5,000-10,000 | 1967 |

| C3 AI | Scaleups | 1,000-5,000 | 2009 |

| DataRobot | Scaleups | 500-1,000 | 2012 |

| Rescale | Scaleups | 100-500 | 2011 |

| Cogniac Corporation | Start-ups | 50-100 | 2015 |

| Falkonry | Start-ups | 50-100 | 2012 |

| Fero labs | Start-ups | 10-50 | 2015 |

| MachineMetrics | Start-ups | 10-50 | 2014 |

| Narrative Wave | Start-ups | 10-50 | 2014 |

| Predictronics | Start-ups | 50-100 | 2013 |

| Sight Machine | Start-ups | 10-50 | 2011 |

| Vanti | Start-ups | 10-50 | 2019 |

Note that we typically consider B2B reviews, but since large manufacturing AI providers have more reviews, overshadowing smaller startups, we chose not to focus on review data for this list.

While identifying the top manufacture AI tools, we took into account two factors:

- Number of employees to classify the tools into categories such as scale-ups, startups, and big tech providers based on their size.

- Pure players that delivers advanced AI systems designed for manufacturing processes.

- For instance, some tech providers mention AI tools for manufacturing, including customizable project management AI tools and AI-driven production planning tools. These are complementary solutions rather than direct manufacturing software.

Big Tech’s manufacturing AI solutions

Big Tech Manufacturing AI vendors represent industry giants with extensive resources and global reach. These established players leverage their vast technological infrastructure to provide comprehensive AI solutions for manufacturing. Their offerings include various applications, from predictive maintenance and quality control to supply chain optimization, driving innovation and efficiency across the manufacturing landscape.

1.) AWS Industrial solutions

AWS, a subsidiary of Amazon, offers a comprehensive suite of cloud services, including AI solutions tailored for the manufacturing sector. Their platform provides scalable and flexible solutions, enabling manufacturers to leverage advanced analytics, machine learning, and IoT for improved operational efficiency and innovation.

Key features

AWS delivers a set of tools for data analytics, AI based predictive maintenance, and process optimization. Its cloud-based infrastructure allows manufacturers to deploy and scale AI applications seamlessly.

2.) GE Additive

General Electric (GE) incorporates AI to enhance manufacturing processes. GE Additive focus on predictive maintenance, asset performance management, and quality control, helping manufacturers reduce downtime and improve overall equipment effectiveness (OEE).

Key features

GE’s AI applications leverage data from industrial equipment and sensors to predict equipment failures, optimize maintenance schedules, and ultimately drive operational excellence in manufacturing.

3.) Google Cloud AI in Manufacturing

Google Cloud offers several AI solutions tailored for the manufacturing industry, providing tools for predictive analytics, supply chain optimization, and quality control. Leveraging Google’s manufacturing data engine solution, manufacturers can gain valuable insights into their operations.

Key features

Google Cloud AI in Manufacturing integrates with other Google Cloud services, offering a holistic approach to data analysis, enabling manufacturers to make informed decisions and drive efficiency in their production processes.

4.) IBM Watson IoT for Manufacturing

IBM Watson IoT for Manufacturing combines IoT and AI to empower manufacturers with advanced analytics and cognitive insights. The platform enables predictive maintenance, quality assurance, and supply chain optimization, fostering intelligent decision-making in the manufacturing domain.

Key features

IBM Watson IoT leverages machine learning algorithms to analyze sensor data, providing manufacturers with actionable insights to enhance product quality, reduce downtime, and optimize production workflows.

5.) Microsoft Azure AI for Manufacturing

Microsoft Azure offers a suite of AI solutions designed specifically for the manufacturing sector. The platform integrates AI, IoT, and analytics to improve production efficiency, quality control, and supply chain management for manufacturers.

Key features

Microsoft Azure AI for Manufacturing provides tools for predictive maintenance, anomaly detection, and process optimization, allowing manufacturers to transform their operations through data-driven decision-making.

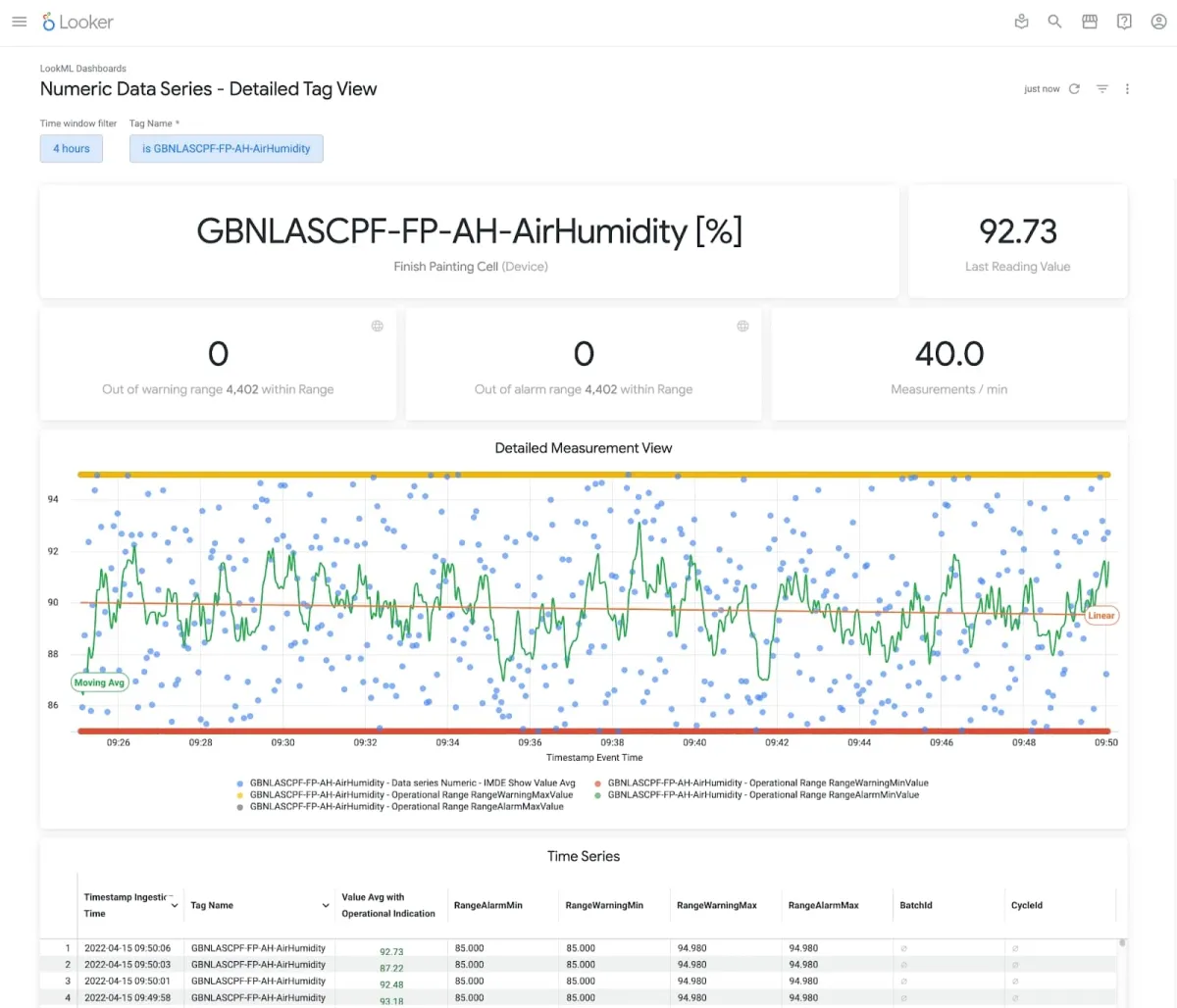

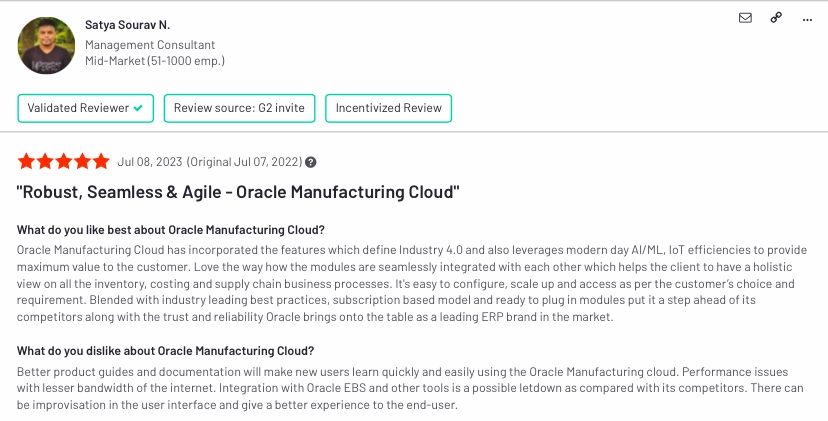

6.) Oracle Manufacturing Cloud

Oracle’s AI solutions for manufacturing focus on enhancing operational efficiency and decision-making. The platform integrates AI capabilities into various manufacturing processes, from supply chain management to quality control, helping organizations adapt to dynamic market demands.

Key features

Oracle’s AI applications enable manufacturers to gain real-time insights, optimize inventory management, and streamline production processes, fostering agility and competitiveness in the manufacturing landscape.

Pros & Cons

Pros

- AI/ML and IoT integration: Leverages modern AI/ML and IoT efficiencies, enhancing overall functionality and value.

- Configurability and scalability: Easy to configure, scale up, and customize according to customer preferences and requirements.

Cons:

- Documentation Improvement: Lack of comprehensive product guides and documentation for new users, hindering quick and easy learning.

- Performance Issues with low bandwidth: Faces performance issues when operating with limited internet bandwidth.

Manufacturing AI scale-ups

Scale-ups are manufacturing AI solutions that have surpassed the startup phase and are experiencing rapid growth and scalability. These firms have demonstrated the effectiveness of their solutions and are expanding their impact on manufacturing processes and customer satisfaction.

7.) Augury:

Augury specializes in predictive maintenance and machine health monitoring for manufacturing. Their platform integrates AI and IoT to analyze machine data, enabling manufacturers to predict equipment failures, reduce downtime, and optimize maintenance schedules.

Key features

Augury’s platform offers continuous monitoring of machine health, leveraging AI algorithms to detect anomalies and predict potential issues. The real-time insights empower manufacturers to implement proactive maintenance strategies, improving overall equipment reliability.

8.) C3 AI

C3 AI is a focused manufacturing AI software, which integrates AI, IoT, and big data analytics to drive digital transformation in manufacturing processes, enhancing operational efficiency, and facilitating data-driven decision-making.

Key features

C3 AI’s platform provides a comprehensive suite of tools for predictive analytics, process optimization, and quality control. It enables manufacturers to harness the power of AI and advanced analytics to gain insights that drive innovation and competitiveness.

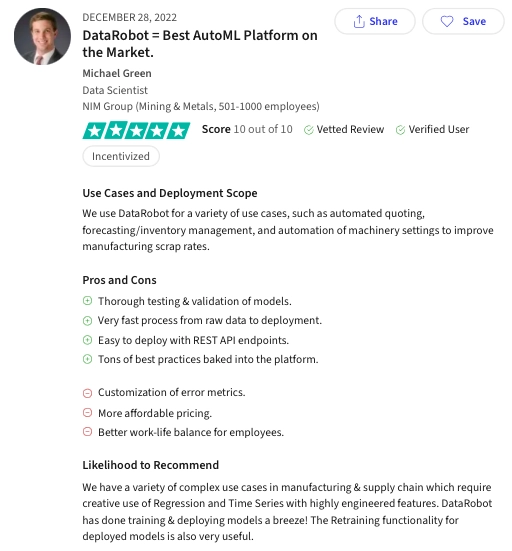

9.) DataRobot

DataRobot is a automated machine learning provider, empowering organizations to build and deploy machine learning models at scale. In manufacturing, DataRobot’s AI solutions are applied to optimize processes, improve quality, and enhance decision-making.

Key features

DataRobot’s platform streamlines the machine learning model development process, making it accessible to a broader audience within manufacturing organizations. It facilitates predictive modeling, anomaly detection, and optimization, contributing to improved operational outcomes.

Pros & Cons

Pros:

- Easy Deployment with REST API endpoints: Simplifies deployment through REST API endpoints, enhancing accessibility and integration capabilities.

- Versatility in use cases: Well-suited for a variety of complex use cases in manufacturing and supply chain, including automated quoting, forecasting, inventory management, and machinery settings automation.

Cons:

- Limited customization of error metrics: Users may find limitations in the customization of error metrics, potentially restricting the ability to tailor evaluations to specific needs.

10.) Rescale:

Rescale focuses on high-performance computing (HPC) solutions for manufacturing, enabling organizations to leverage the power of AI and simulation for product design, testing, and optimization. Their platform provides cloud-based HPC resources to accelerate complex simulations and analyses.

Key features

Rescale’s platform allows manufacturers to scale their computational resources dynamically, facilitating faster and more efficient simulations. This is particularly valuable for industries such as aerospace and automotive, where complex simulations are crucial for product development and innovation.

Manufacturing AI start-ups

Startups in the Manufacturing AI domain represent emerging ventures characterized by their keen focus on addressing specific challenges within the industry. Unlike industry giants, these companies are often more nimble, catering niche aspects of manufacturing processes.

11.) Cogniac Corporation

Cogniac Corporation specializes in visual-based AI solutions for manufacturing, offering computer vision applications to enhance quality control and inspection processes. The company’s platform utilizes advanced machine learning algorithms to analyze and interpret visual data, empowering manufacturers to improve product quality and reduce defects.

Key features

Cogniac’s AI platform is designed to handle complex visual inspection tasks, enabling automated identification of defects and anomalies in real-time. Its customizable and adaptive algorithms make it well-suited for a variety of manufacturing environments.

12.) Falkonry

Falkonry focuses on predictive operations and machine learning for manufacturing, providing a platform that helps organizations predict and prevent operational disruptions. The platform utilizes machine learning models to analyze time-series data, enabling manufacturers to anticipate equipment failures and optimize maintenance schedules.

Key features

Falkonry’s platform excels in predictive analytics, offering manufacturers the ability to monitor equipment health, predict failures, and proactively address maintenance needs. Its user-friendly interface empowers domain experts to build and deploy predictive models without extensive data science expertise.

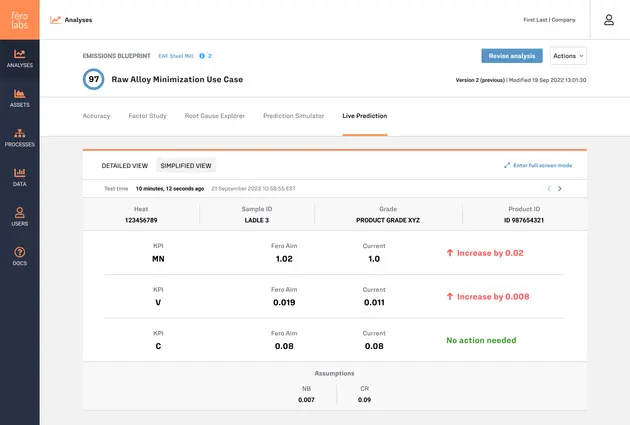

13.) Fero Labs

Ferolabs specializes in AI-driven solutions for process optimization in manufacturing. The company’s platform leverages machine learning algorithms to analyze and optimize complex manufacturing processes, enhancing efficiency and reducing operational costs.

Key features

Ferolabs’ AI applications provide manufacturers with insights into process bottlenecks, inefficiencies, and opportunities for improvement. The platform facilitates data-driven decision-making, allowing organizations to streamline operations and enhance overall productivity.

14.) MachineMetrics

MachineMetrics offers an industrial IoT platform with a focus on real-time data analytics for manufacturing. The platform collects and analyzes data from manufacturing equipment, providing manufacturers with insights into machine performance, production efficiency, and overall equipment effectiveness (OEE).

Key features

MachineMetrics’ platform enables manufacturers to monitor and optimize production processes in real-time. Its features include machine connectivity, performance analytics, and predictive maintenance capabilities, helping organizations maximize operational efficiency.

15.) Narrative Wave

Narrative Wave specializes in AI-driven solutions for supply chain optimization in manufacturing. The company’s platform leverages advanced analytics and machine learning to enhance demand forecasting, inventory management, and logistics planning.

Key Features

Narrative Wave’s platform helps manufacturers optimize their supply chain by providing accurate demand forecasting, reducing excess inventory, and improving overall supply chain visibility. The AI-driven insights enable organizations to make data-driven decisions for improved efficiency.

16.) Predictronics

Predictronics focuses on AI based predictive maintenance solutions for manufacturing to forecast equipment failures and optimize maintenance strategies. The company’s platform analyzes sensor data to predict potential issues, helping manufacturers reduce downtime and extend the lifespan of critical assets.

Key features

Predictronics’ predictive maintenance platform offers real-time monitoring, anomaly detection, and failure prediction, allowing manufacturers to implement proactive maintenance practices and enhance the reliability of their machinery.

17.) Sight Machine

Sight Machine specializes in manufacturing analytics, offering a platform that transforms manufacturing data into actionable insights. The company’s AI-driven analytics enable manufacturers to monitor production performance, optimize processes, and drive continuous improvement.

Key features

Sight Machine’s platform provides manufacturers with a comprehensive view of their operations, facilitating data-driven decision-making. The platform includes features for performance monitoring, quality control, and process optimization, empowering organizations to achieve operational excellence.

18.) Vanti

Vanti focuses on AI solutions for energy efficiency and sustainability in manufacturing. The company’s platform leverages machine learning to optimize energy consumption, reduce environmental impact, and enhance overall sustainability practices within manufacturing facilities.

Key features

Vanti’s AI applications help manufacturers achieve energy efficiency goals by analyzing data related to energy consumption, identifying opportunities for optimization, and providing actionable recommendations. The platform supports organizations in aligning with sustainability initiatives while improving operational efficiency.

FAQ

What is Manufacturing AI?

Manufacturing AI, or Artificial Intelligence in Manufacturing, refers to the application of advanced technologies like machine learning, data analytics, and automation within the manufacturing sector. It involves leveraging intelligent systems to enhance production processes, improve efficiency, and make data-driven decisions.

Manufacturing AI solutions can be applied to various areas, including predictive maintenance, quality control, supply chain optimization, and process automation. By analyzing vast datasets and optimizing operations, it aims to increase productivity, reduce costs, and drive innovation, ushering in a new era of smart and adaptive manufacturing practices.

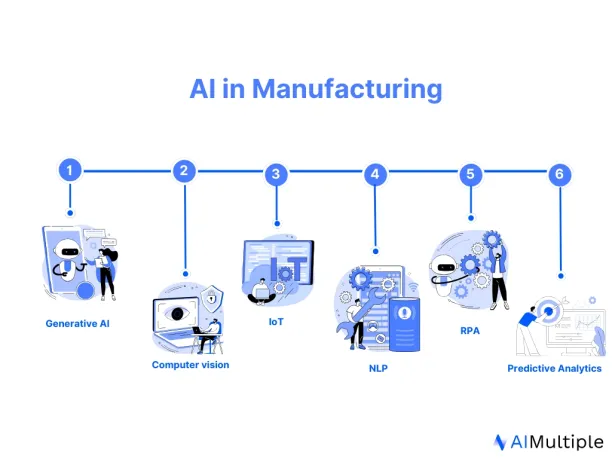

How is AI used in manufacturing industry?

– Generative AI in product design: One transformative AI technology in manufacturing is generative AI. By leveraging a generative AI software, companies can optimize components for specific criteria such as weight, strength, or cost. This innovation in product design enhances efficiency and fosters continuous improvement in manufacturing processes. Discover more on generative AI in manufacturing.

– IoT for predictive maintenance: Internet of Things (IoT) devices form a critical component in manufacturing, collecting real-time data from machinery. Applied to predictive maintenance, IoT facilitates the analysis of equipment health, enabling proactive strategies to prevent breakdowns. This not only reduces downtime but also extends the operational lifespan of crucial assets. Explore more on IoT in manufacturing.

–Computer vision for quality control: By employing machine learning algorithms, computer vision systems inspect products for defects in real-time, ensuring consistent and high-quality production. This application of machine vision technology significantly enhances product quality and reduces waste. Read more on computer vision applications in manufacturing.

– Natural Language Processing (NLP) for data analysis: In manufacturing AI, Natural Language Processing (NLP) contributes to efficient data analysis. By understanding and interpreting textual data, NLP enhances communication and provides valuable insights for data-driven decision-making. This application aids in optimizing workflows and identifying areas for process improvement.

–Predictive analytics for supply chain optimization: Predictive analytics, powered by machine learning, transforms supply chain management in manufacturing. This technology analyzes both historical data and real-time data to provide accurate demand forecasts. Manufacturers leverage this information to optimize inventory levels, minimize holding costs, and enhance overall supply chain efficiency. Find out more on manufacturing analytics.

– Robotic Process Automation (RPA) for streamlining operational processes: RPA emerges as a pivotal technology in manufacturing for automating routine operational processes. RPA in manufacturing ensures redirect their focus toward more strategic initiatives, thereby increasing overall productivity and operational agility. Learn other automation tools that can replace RPA, such as intelligent automation in manufacturing.

Further reading

Explore more on AI use cases in any manufacturing process by exploring:

- Top 12+ IT Automation Software: Vendor Benchmarking

- Top 10 No-code Manufacturing Use Cases & 6 Vendors

- 6 Reasons to Use Process Mining in Manufacturing

If you have more questions, do not hesitate to contact us:

External sources

- 1. Google Cloud solutions for manufacturing operations | Google Cloud Blog. Google Cloud

- 2. Oracle Manufacturing Cloud Reviews 2025: Details, Pricing, & Features | G2.

- 3. DataRobot Reviews & Ratings 2025. TrustRadius

- 4. Industrial Data Analytics | Manufacturing Industry… | Fero Labs.

- 5. Generative AI Manufacturing Optimization Platform | Vanti.

Comments

Your email address will not be published. All fields are required.