AIMultiple collects data on hundreds of thousands of B2B vendors from the web and surveys. Based on our experience, if you are looking for data to

- Build AI models with data:

- Collected by humans, see AI data collection services

- From the web, see web data collectors

- Improve your understanding of a market (e.g., by running a survey), see market research data collection services

Top 12 AI data collection services

Despite the efficiency of web data collection and synthetic data generation, human-generated data remains essential for AI development. Here, we compare the top 12 data collection services and data partners that provide human-generated datasets for AI training.

| Service | Data Annotation As A Service | Mobile Application | API Availability | ISO 27001 Certification | Code of Conduct |

|---|---|---|---|---|---|

| LXT | ✅ | ✅ | ✅ | ✅ | ✅ |

| Appen | ✅ | ✅ | ✅ | ✅ | ✅ |

| Prolific | ❌ | ❌ | ✅ | ❌ | ✅ |

| Amazon Mechanical Turk | ✅ | ❌ | ✅ | – | ❌ |

| Telus International | ✅ | ❌ | ✅ | ❌ | ❌ |

| TaskUs | ✅ | ❌ | ✅ | ✅ | ✅ |

| Summa Linguae Technologies | ✅ | ✅ | ✅ | ✅ | ❌ |

| Surge AI | ✅ | ❌ | ✅ | ✅ | ❌ |

| Toloka AI | ✅ | ✅ | ✅ | ✅ | ✅ |

| Innodata Inc | ✅ | ❌ | ✅ | ✅ | ❌ |

| DataForce by Transperfect | ✅ | ✅ | ❌ | ✅ | ❌ |

We consider a company to be data collection-focused if it offers data collection as its key offering on its website.

- Inclusion criteria: 50+ employees and an AI data generation or collection offering.

- Sorting: Vendors with links to their websites are sponsors of AIMultiple and are listed at the top. The remaining services are ranked based on their total number of reviews.

- Explanation of columns: See AI data collection service selection criteria

- Apart from Surge AI, which only offers speech and text data, all companies cover a wide array of data types (Image, Video, Audio, Text, etc.).

- In Table 1, a company is assumed to follow a code of conduct if it has a code of conduct page on its website.

Top 5 web data collectors

Web data collectors, or web scraper APIs, utilize automated web scraping and proxy solutions to gather large-scale web data from public sources:

| Vendors | Starting price (mo) | PAYG plan | Free trial |

|---|---|---|---|

| Bright Data | $500 | ✅ | 7 days |

| Oxylabs | $49 | ❌ | 7 days |

| Smartproxy | $29 | ❌ | 3K free requests |

| Zyte | $100 | ✅ | $5 free credit for a month |

| Nimble | $150 | ❌ | 7 days |

Detailed analysis of AI data collection services

This section evaluates each data collection company based on customer reviews from leading B2B review platforms like G21 , using the latest company news and customer feedback.

1. LXT

LXT is a crowdsourcing platform specializing in data collection services for AI model training and market research. The task is broken down into micro-tasks and distributed to a global network for quicker completion. So, companies can obtain large amounts of human-generated data in a shorter period of time. It specializes in tasks such as AI data collection or generation, data annotation, data categorization, and web research.

Here is a list of LXT’s data solutions:

- AI training data collection or generation (Done by humans)

- Image & video datasets (Multiple formats and specifications)

- Audio and speech datasets (Multiple languages and dialects)

- Text datasets

- Data annotation service

- Research/survey data collection

- Reinforcement learning from human feedback (RLHF) services for AI development

Pros and cons:

- Based on our analysis of the competitors and user reviews, we found LXT’s AI data services to be the best in the market.

- Customers find LXT’s AI services helpful, and its crowd is reliable.

- A customer review regarding LXT’s efficient data annotation services and its prices.

2. Appen

Appen offers various AI-related managed services and is a popular player in the market. However, the company is facing a significant decline in terms of customer satisfaction and finances. The company’s condition has affected its services, which has led to losing customers.

Appen provides a range of AI-related managed services and is a popular name in the market. However, the company has faced a significant decline in customer satisfaction and financial stability. This downturn has impacted its services, resulting in the loss of customers.

- Data collection & generation (image, video, text, audio, speech)

- Data annotation

- Data validation

Pros and cons:

- Appen has lost large customers like Google, and its stock price has declined substantially, which may reflect on the user experience.2

- While Appen’s user interface is liked, its reliability has been an issue for some customers.

3. Prolific

Prolific is another data collection company that offers AI data services through a crowdsourcing model. It is used by organizations for AI data, academic research, and market research purposes. Learn about prolific alternatives here.

Here is a list of their offerings:

- AI data collection & generation

- AI training and evaluation

- Academic research data

- Online survey participants

Pros and cons:

- Prolific does not highlight data annotation as a service on its website. This might be an issue for customers who may prefer a single provider for data collection and annotation.

- Most of the customer reviews were regarding Prolific’s research data services, which may indicate that its AI data services are less popular.

4. Amazon Mechanical Turk (MTurk)

Amazon Mechanical Turk, or MTurk, offers a crowdsourcing platform or marketplace where businesses can outsource tasks and jobs to a network of workers who can perform these tasks virtually. Here is a list of their offerings:

- AI data collection and generation

- Data annotation and labeling

- Market research & surveys

- Academic research

- Other data services

Pros and cons:

- Researchers have observed that AI-generated responses are common on the platform.3

- Customers also identified that most workers on MTurk’s platform are not English speakers.

- A customer found its data collection service to be efficient, but the quality of the data was low.

Learn about Amazon Mechanical Turk alternatives here.

5. Telus International

Telus International claims to offer customer experience (CX) and digital IT solutions. Telus also offers data services through a crowdsourcing model. Its data solutions include:

- Data collection & annotation

- Data generation (image, audio, video, text, speech)

- Data validation and relevance

Pros and cons:

- We did not find any reviews regarding its data collection service, which indicates that the company might focus on its customer experience and data annotation services.

- According to reviews, Telus’s network is diverse, but its service is slow.

6. TaskUs

While TaskUS’s key offerings revolve around customer experience, it also offers the following AI services:

- Data collection and generation (image, video, audio, and text)

- Data annotation

- Data collection for research

Pros and cons:

- The company offers data collection and annotation for all data types.

- The crowd size is significantly smaller than other AI data services like Clickworker and Appen.

- The company does not offer AI data collection as its primary offering since it was not mentioned first on its website. The customer reviews also suggested that its primary focus is not data collection, since no reviews for data collection were found.

7. Summa Linguae Technologies

Summa Linguae Technologies also operates through a crowdsourcing platform. Its offerings include:

- Data collection for AI models

- Data annotation

- Data translation

8. Surge AI

Based in California, Surge AI provides training data for machine learning models through a crowdsourcing platform. Surge AI claims to focus on collecting and labeling data for Large Language Models (LLMS)

- AI data labeling and annotation

- AI data collection

- And other human-generated data services

Pros and cons:

- The company offers RLHF and data for LLMs

- The company does not offer visual datasets

- There were no customer or worker reviews found on review platforms, which makes it difficult to evaluate the company’s performance from a customer’s perspective.

9. Toloka AI

Toloka AI is also a data collection company that uses a crowdsourcing model to collect and generate data for AI models. The company claims to provide various services such as data labeling, data cleaning, and data categorization to enhance machine learning models.

Pros and cons of working with Toloka AI

- The company offers data collection and annotation of all data types (Image, video, text, audio).

- Toloka AI has a significantly smaller crowdsourcing platform with a network of around 200K, which is relatively smaller than its competitors.

10. Innodata Inc.

Based in New Jersey, Innodata Inc. is also a data collection and generation company that offers various AI solutions through crowdsourcing. Its solutions include data collection and annotation.

Pros and cons:

- The company offers a significantly smaller crowdsourcing platform than its competitors. With a crowd size of only over ~5000 workers.

- The company does not have a strong online presence, as we did not find any customer or worker reviews on B2B or B2C platforms.

11. DataForce by Transperfect

DataForce by TransPerfect offers data collection and annotation for AI and machine learning projects. It provides services like speech and natural language processing data, image and video annotation, and more. Its data services include:

- Data collection and generation

- Data annotation

- Data transcription

- Data moderation

Pros and cons:

- The company claims to have a network of over 1 million contributors, which may make its datasets more diverse.

- However, its performance and claims can not be verified since no customer reviews were found from B2B or B2C review platforms like G2.

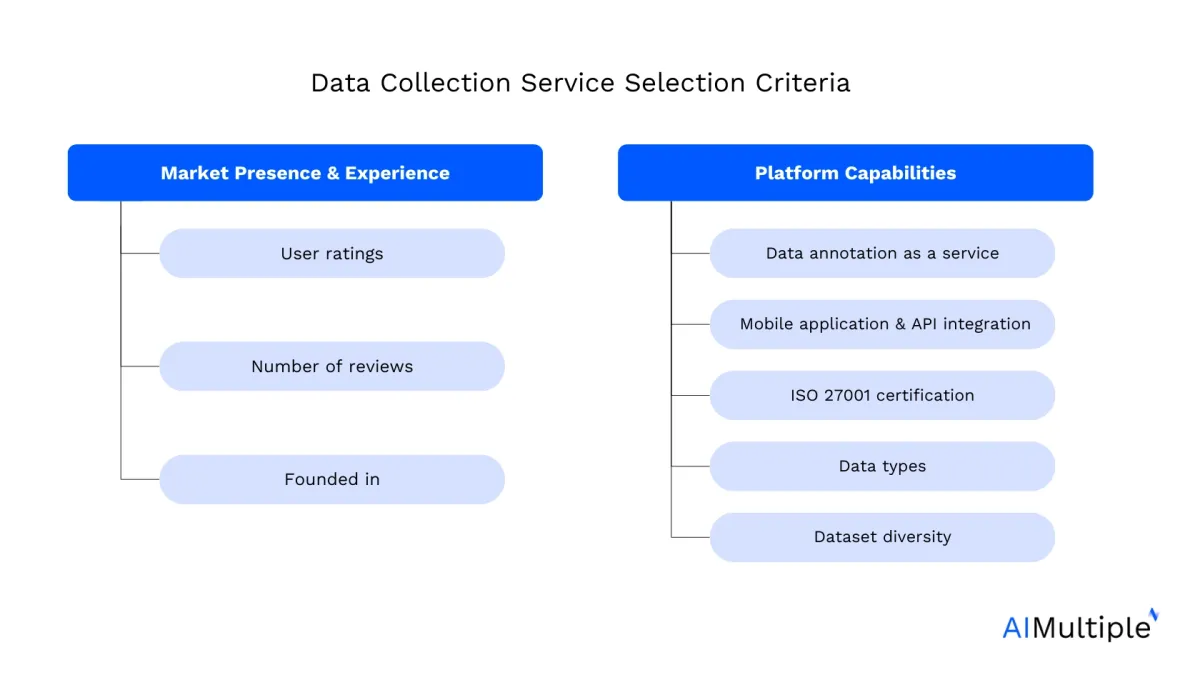

AI data collection service selection criteria

Every company/project’s data needs are different; therefore, it can be difficult to select the right data collection service that fulfills your requirements. We used the following criteria to analyze the top service provider in the market. The criteria are divided into 2 categories: market presence & experience, and features.

Market presence of top data collection services

1. User ratings

The user ratings from B2B review platforms such as G2, TrustRadius, and Capterra can help buyers understand the overall performance of the data collection service provider. A higher user rating from 50+ reviews can give a comprehensive understanding of the company’s performance.

2. Number of reviews

A larger number of reviews on B2B review platforms indicates the company has a large user/customer base, and you can get a better understanding of the customers’ perspective and their level of satisfaction.

3. Founded in

The age of the company helps potential customers understand the experience the service provider has in a specific field. In our experience, an older company usually offers a more refined service. However, this is not always the case since some companies can gain more expertise in a shorter period of time. Therefore, do not recommend using this criterion on its own.

Platform capabilities of top data collection services

4. Data annotation as a service

Data is useless to machine learning models without annotation. Therefore, it can be efficient if the company also offers data annotation as a complementary or side service, so the data you receive is ready to be used.

5. Mobile application & API integration

It is also crucial to check what capabilities the data collection platform of the vendor offers. Do they offer a mobile application or API integration capability?

6. ISO 27001 certification

With rising cybersecurity threats, having effective data protection practices in place is essential. We looked for the ISO 27001 certification.

7. Code of conduct

Your business partner’s unethical practices will impact your reputation. Therefore, make sure the service provider follows fair trade and a clear code of conduct of fair practices towards workers.

8. Data types

We consider whether the companies covered all data types. For instance, the required data for an automated driving system would be images of pedestrians, roads, streets, vehicles, etc.

9. Dataset diversity

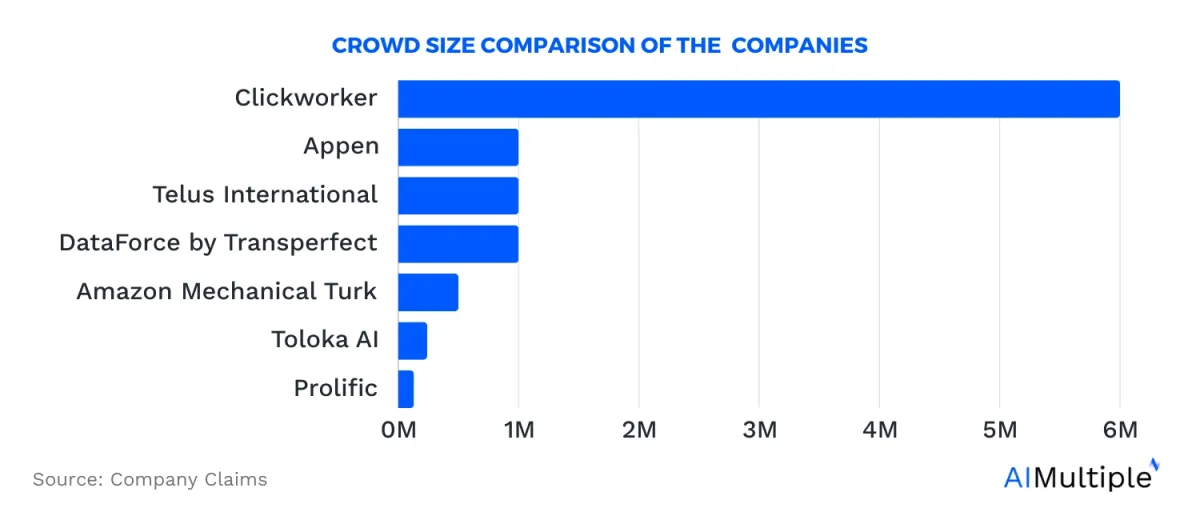

To evaluate the diversity level, we checked the size of the crowd or the number of participants in the company’s network. For instance, for a system to provide accurate output in various languages, the company should gather multilingual data through a global crowd. The larger the crowd, the more languages and dialects the network covers. For this, we created a separate comparison:

Figure 1. Crowd size comparison of the data collection service providers

The Crowd represents the number of workers in the company’s network of text data collectors or generators.

Notes for Figure 1:

- In Figure 1, Innodata Inc. and TaskUS were not included since their crowd size was less than 100 K.

- For Figure 1, some vendors were also excluded since their crowd size data was not found on their websites.

Why work with an AI data collection service provider?

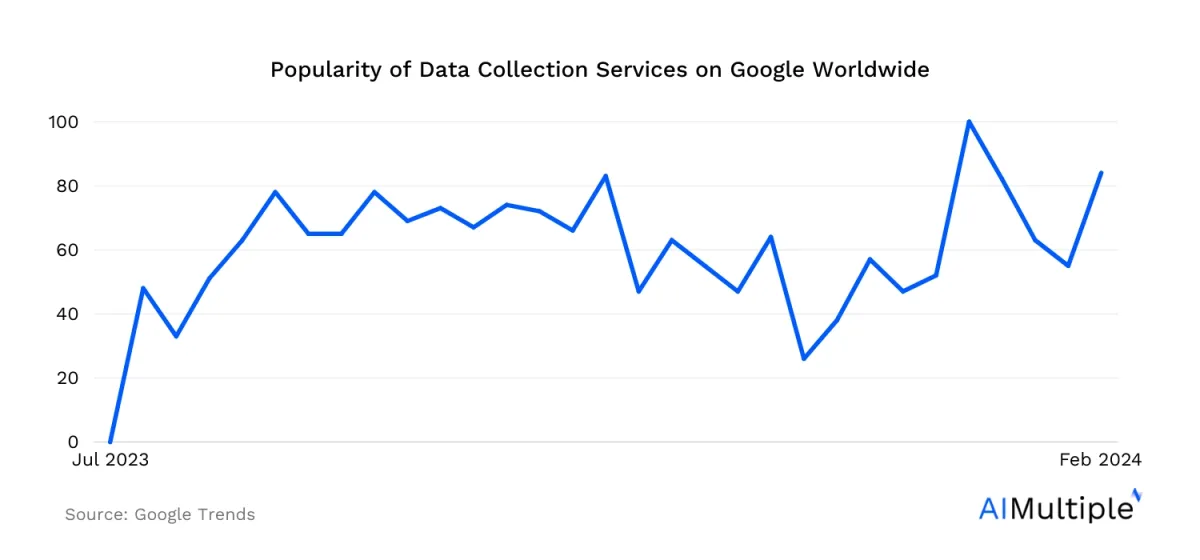

This section highlights some benefits of working with an AI data collection partner. The popularity of data collection services online:

1. Quality assurance

Data collection service providers often have rigorous quality control measures and standards in place to ensure the accuracy and relevance of the data being collected. They employ dedicated teams of data scientists and analysts who follow stringent protocols to maintain data integrity. This high level of quality assurance can significantly improve the performance of your AI and ML models, which heavily depend on data quality for optimal outcomes.

To maintain the quality of the AI tool, it is important to continuously develop and improve it, so it continues to provide valuable insights. Working with a data collection partner can provide you with improved datasets to re-train your models whenever required.

You can also read this to learn more about data quality assurance.

2. Scalability and speed

Collecting and processing large amounts of data can be time-consuming and difficult to scale, especially for businesses without the necessary resources or expertise. Data collection companies can quickly scale up their operations to meet your data needs, ensuring a steady stream of well-curated data. They have the manpower, technology, and processes in place to handle large-scale data operations, allowing for faster completion of projects.

3. Expertise and specialization

Data collection service providers specialize in data-related operations and thus have a deep understanding of various data collection methodologies, data processing techniques, and compliance requirements. They are capable and equipped to handle a wide range of data types (structured, unstructured, semi-structured) and can efficiently work with various data sources. This expertise can be incredibly beneficial, especially when working with complex AI and ML projects with exclusive requirements.

4. Higher level of diversity

Some AI systems require diverse datasets to provide an accurate output. Some data collection service providers use a crowdsourcing platform for collecting data. This approach has a unique advantage in that it allows for the collection of a large volume of diverse data quickly.

Crowdsourced data can help companies access a large pool of online talent, making it a good fit for training robust and generalized AI and ML models. Moreover, the flexibility of crowdsourcing allows for the collection of data that may not be easily accessible through other methods, such as data reflecting rare events or specific regional characteristics.

Crowdsourcing is only one of the data collection methods. Check out this article to learn more about different techniques to collect data.

5. Cost-effectiveness

Working with a data collection service can be cost-effective as it helps avoid high infrastructure costs associated with data handling processes and eliminates the expenses related to hiring and training in-house data experts.

Additionally, these services offer scalable solutions that adapt to a company’s fluctuating data needs, ensuring payment only for services used. Their expertise can drive efficiency, leading to time and cost savings.

Lastly, they mitigate the risk of costly errors in data collection and processing, ensuring accuracy that leads to better AI/ML model performance. Thus, despite an upfront cost, long-term savings can make these services a cost-effective option for many businesses.

6. Additional offerings

Data collection service providers also offer extra services that a company might require, along with data collection. Services like:

- Performing data annotation

- Conducting online surveys or market research

- Data transcription, etc.

Market research data collection services

As the value of data increases for market research, more companies are working with data collection partners. This section lists the top data collection services for market research. Here is the comparison:

Top 6 market research data collection companies

| Services | Offerings | # of Employees |

|---|---|---|

| Kantar | AI-driven trend identification from web data, trend reports, consumer/business insights | 34k+ |

| Ipsos | Custom panels, interviews, mystery shopper, consumer insights, brand/product testing, message testing, healthcare studies, public opinion polling | 17K+ |

| LXT | Market research, Survey participants, Store Checks, AI data collection, AI data annotation, | 1.1K |

| Edelman DXI | Social listening, competitive analysis, content auditing, media planning, risk forecasting, workforce analytics | 445 |

| IMS Marketing | Customer feedback, product/market testing, competitor analysis, market segmentation, audience research, brand perception | 48 |

We only selected companies with 45+ employees and market research offerings.

FAQs for data collection services

What do data collection services do?

AI data collection services harness a vast contributor network to gather new or existing AI training data, enabling developers and businesses to concentrate on other AI development facets besides dataset preparation.

Why are data collection services necessary?

With regulations tightening and data access becoming more challenging, businesses and AI developers can obtain scalable and tailored datasets more efficiently by working with data collection services.

Why do we need data collection services?

With the volume of data required and managed for AI projects, it can be resource-heavy to perform such tasks in-house. Working with a data collection service provider can help business leaders fulfill their data needs more efficiently.

*A data collection service can offer:

*A faster service

*Human-generated data (image, video, audio, text, etc.)

*More diverse and multilingual datasets

*Scalable services

*A cheaper option than in-house data collection.

How do data collection services provide data?

Data collection services usually have a vast network of contributors that generate data on demand for different use cases. Some companies also offer pre-packaged datasets that have been gathered in the past.

Is crowdsourcing an effective method of gathering data?

Data crowdsourcing can benefit your business by enabling access to a large network of talent that gathers or generates fresh data on demand. Crowdsourcing platforms can provide diverse datasets that are cheaper and faster to obtain.

Further reading

- Top 4 Data Collection Methods

- Crowdsourcing Platforms Comparison & Selection Guide

- Crowdsourced AI Data Collection Benefits & Best Practices

- Quick Guide to Datasets for Machine Learning

- Top 3 Amazon Mechanical Turk Alternatives & Their Evaluation

- Appen Evaluation & Top 3 Alternatives

Comments

Your email address will not be published. All fields are required.