With the global supply chain management market valued at almost $16 billion in 2020 and projected to nearly double to $31 billion by 2026, businesses are racing to improve integration and resilience to stay competitive.1 Supply chain software alone is expected to grow at a 4% annual rate through 2028, reflecting how urgently companies invest in smarter, more connected operations.2

Discover the top 10 actionable best practices to strengthen supply chain integration and resilience, making end-to-end networks more connected, adaptive, and competitive.

10 best practices for effective supply chain integration

Achieving successful supply chain integration requires more than just adopting new tools; it calls for a thoughtful blend of strategies, technologies, and cultural alignment across the entire supply chain network.

Below are 10 best practices to help businesses maximize the benefits of supply chain integration, improve supply chain efficiency, and gain a sustainable competitive advantage.

1. Establish clear goals and objectives

To synchronize your supply chain integration efforts, it’s essential to start by setting clear, measurable goals and objectives. These goals help align all supply chain members, from raw material suppliers to logistics providers, ensuring everyone is working toward the same outcomes.

For example, a company may aim to reduce supply chain lead times, optimize inventory levels, improve customer satisfaction, and enhance supply chain performance. These objectives provide a strategic roadmap that guides the integration process, helping prioritize investments in supply chain technology and integration strategies to maximize operational efficiency.

2. Leverage composable digital solutions

Integrated supply chain management relies heavily on the right technologies. Composable and no-code digital solutions offer businesses the flexibility to design, adapt, and improve supply chain processes quickly without heavy IT involvement.

For instance, a retailer might use a no-code platform to create a custom inventory management system that integrates real-time data from suppliers, manages order processing, and improves fulfillment speed. Such solutions boost agility, allowing companies to respond rapidly to shifts in customer demand and market conditions while enhancing the entire supply chain’s responsiveness.

3. Achieve end-to-end visibility

End-to-end visibility is a foundational element of seamless supply chain integration. It enables businesses to monitor supply chain activities across the integrated supply chain, ensuring transparency from the sourcing of raw materials to the final delivery to customers.

To achieve this, companies can:

- Deploy IoT devices, GPS, and RFID for real-time tracking of shipments and inventory.

- Integrate data across supply chain systems to create a unified, centralized view.

- Use blockchain technology for secure and transparent data sharing.

This visibility reduces risks, improves responsiveness, and supports sustainability initiatives by providing detailed insights into supply chain operations.

4. Foster collaboration and information sharing

A key component of effective supply chain integration is building strong relationships among internal teams and external stakeholders. Encouraging cross-functional teams to work closely with other stakeholders, such as suppliers, distributors, and logistics providers, fosters a culture of openness and trust.

Investing in collaborative tools and integrated systems that facilitate information sharing ensures that all supply chain partners can access critical data. This leads to better coordination, optimizes production schedules, and improves supply chain processes. Such collaboration supports functional integration and enhances the organization’s ability to meet customer expectations.

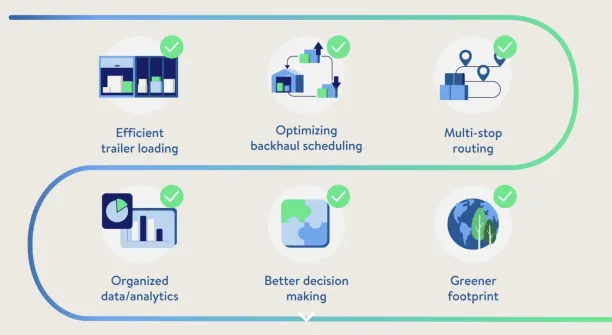

5. Adopt a data-driven approach

Leveraging big data, advanced analytics, AI, and machine learning allows companies to gain actionable insights into their supply chain operations. A data-driven approach empowers businesses to identify inefficiencies, reduce costs, and make smarter decisions across the integrated supply chain.

For example, a manufacturer can use analytics to monitor supplier performance, anticipate disruptions, and adjust production schedules accordingly. This improves supply chain efficiency, reduces inventory holding costs, and enhances customer satisfaction by ensuring timely deliveries.

6. Implement standardized processes and metrics

Standardizing key processes and performance metrics across the supply chain network creates a consistent operational framework. This reduces confusion, aligns expectations among supply chain members, and optimizes communication.

Standardized metrics also provide a clear basis for evaluating supply chain performance, enabling companies to benchmark against best practices, identify gaps, and implement improvements. This structured approach supports both vertical integration and horizontal integration efforts, enhancing the overall integration process.

7. Align supply chain integration with business strategy

Successful supply chain integration requires alignment with the company’s broader business strategy. This means ensuring supply chain activities support strategic priorities such as market expansion, product innovation, or sustainability goals.

When integration in supply chains aligns with business objectives, it creates added value that drives competitive advantage, improves efficiency, and delivers greater value to customers.

8. Invest in talent development and cross-training

People are just as important as technology in supply chain integration. By developing internal integration skills and cross-training employees across different departments, businesses can build cross-functional teams capable of understanding and managing key processes across the supply chain network.

This enhances operational flexibility and ensures that knowledge is shared across the organization. Investing in talent improvement strengthens internal integration and improves coordination with external supply chain partners.

9. Prioritize risk management and scenario planning

As supply chains become more global and interconnected, risk mitigation becomes a critical focus. Beyond adopting technologies and processes, businesses should develop integrated risk management frameworks that include scenario planning and stress testing.

By preparing for different risk scenarios, companies can enhance their supply chain resilience, maintain continuity during disruptions, and ensure the integration process is solid against both expected and unexpected challenges.

10. Continuously monitor and improve

Supply chain integration is not a one-time project but an ongoing journey. To ensure long-term success, businesses must commit to continuous monitoring, evaluation, and improvement.

By regularly assessing supply chain performance, companies can identify bottlenecks, adapt to new challenges, and implement innovations that improve efficiency. Establishing a feedback loop that encourages experimentation and innovation helps supply chain managers stay ahead of trends, maintain operational efficiency, and strengthen the integrated supply chain over time.

What is supply chain integration?

Supply chain integration refers to connecting and harmonizing all stages of a product’s journey, from sourcing raw materials and managing the production process to distribution and final consumption.

This integration process involves aligning various supply chain members’ activities, business processes, and systems, including suppliers, manufacturers, distributors, logistics providers, and retailers.

By fostering closer collaboration across the entire supply chain, businesses can achieve effective supply chain integration that improves coordination and information sharing between different departments and external stakeholders.

Integrated supply chain management enhances supply chain efficiency by optimizing production schedules, improving resource utilization, reducing inventory holding costs, and lowering transportation costs. Ultimately, this leads to better supply chain performance, greater customer satisfaction, and a more decisive competitive advantage.

Key components of successful supply chain integration include adopting integrated systems like enterprise resource planning (ERP), using supply chain technology for real-time data sharing, and applying supply chain integration strategies that support communication across the supply chain network.

This enables organizations to improve supply chain visibility and coordinate supply chain activities more effectively, maximizing efficiency across the entire supply chain network.

Examples from leading companies for supply chain integration

Amazon: AI-driven supply chain optimization

Challenge:

Amazon operates one of the world’s largest and most complex supply chains, which faces constant pressure from rising customer expectations, fluctuating demand, and global disruptions such as pandemics and geopolitical tensions. Managing inventory across thousands of warehouses while maintaining fast delivery promises presented significant challenges, particularly in forecasting demand and minimizing excess stock.

Solution:

Amazon leveraged artificial intelligence (AI) and machine learning (ML) to enhance its demand forecasting and logistics optimization. By integrating AI into its supply chain systems, Amazon improved predictive analytics, allowing it to anticipate customer demand shifts accurately.

These tools also optimized warehouse operations and delivery routes, reducing costs and boosting delivery speeds. The result was a more efficient, adaptive, and sustainable supply chain capable of responding rapidly to global challenges.3

Unilever: Integrating AI for sustainability and efficiency

Challenge:

With a vast portfolio of brands and products, Unilever faced challenges aligning its supply chain with growing sustainability goals while keeping operations efficient. The company needed better visibility across its global operations to monitor resource use, reduce waste, and meet consumer demand for eco-friendly products.

Solution:

Unilever partnered with Google Cloud to integrate AI and advanced analytics into its supply chain. This technology provided real-time insights into inventory management, transportation, and environmental factors such as weather impacts on sourcing.

With improved data visibility, Unilever could optimize resource use, reduce carbon emissions, and enhance supply chain responsiveness, achieving sustainability and operational goals.4

Nike: Diversifying supply chain sources during disruptions

Challenge:

Nike faced major supply chain disruptions during the COVID-19 pandemic, which exposed the risks of relying heavily on a limited number of suppliers and manufacturing hubs, particularly in Asia. Factory shutdowns and shipping delays threatened product availability and sales.

Solution:

Nike adopted a diversification strategy to spread risk across a broader supplier base. By expanding sourcing regions and increasing nearshoring efforts, the company reduced its dependence on any single geography.

Nike also invested in digital tools to improve visibility and coordination across its supply network, allowing faster adaptation to changes and minimizing the impact of future disruptions.5

Walmart: Building an integrated supply chain for competitive advantage

Challenge:

Managing a massive retail operation, Walmart faced challenges around inventory accuracy, stockouts, and ensuring a smooth flow of goods across its network. The company needed a way to handle real-time data from thousands of stores to optimize its supply chain operations and stay ahead in a competitive retail environment.

Solution:

Walmart implemented integrated systems, combining advanced barcode scanning and point-of-sale technologies to collect and process real-time sales data. This information fed into centralized supply chain systems, enabling precise inventory management, demand forecasting, and faster replenishment cycles. These improvements allowed Walmart to lower costs and reduce stockouts.6

Figure 1: Walmart Commerce Technologies’ route optimization with AI.https://corporate.walmart.com/news/2024/03/14/walmart-commerce-technologies-launches-ai-powered-logistics-product

Mattel: Enhancing agility in response to market trends

Challenge:

Mattel, a global toy manufacturer, needed to become more agile in responding to fast-changing consumer trends, especially as major product launches like the “Barbie” movie created sudden spikes in demand. The company’s traditional supply chain struggled to pivot quickly enough to capitalize on these surges, risking missed revenue opportunities.

Solution:

Mattel restructured its supply chain operations to prioritize flexibility. The company focused on core, high-demand products and optimized production and distribution processes.

It enhanced demand forecasting and inventory management, ensuring popular products could be produced and delivered rapidly in response to market trends. This approach allowed Mattel to effectively meet the surge in demand from the Barbie movie, maximizing sales and customer satisfaction.7

Why is supply chain integration important today?

1. Increasing globalization

Today’s global economy is highly interconnected, with millions of businesses operating across different countries and regions.8 The expansion of international trade has made supply chains more complex and dynamic, creating a vast supply and demand network between numerous economic agents.

Businesses rely on supply chain management to ensure efficient collaboration between companies and their supply chain partners, a necessary precondition for smooth economic coordination and the successful functioning of the global economy.

Integrated supply chains enable companies to synchronize their operations with international suppliers, raw material suppliers, logistics providers, and distributors, enhancing supply chain integration work across borders.

This extensive integration supports operational efficiency, helping businesses manage logistics planning, optimize production schedules, and the flow of goods and information throughout the entire supply chain.

2. Changing customer expectations

Consumer expectations have shifted significantly due to technological advancements and digital connectivity, with 73% of consumers saying that customer experience plays a key role in their purchasing decisions9 and 89% indicating they are more likely to buy again after a positive customer service experience.10

Today’s customers demand fast, reliable, personalized service, requiring an integrated supply chain process. By enhancing supply chain integration, businesses can become more resilient and flexible, quickly adapting to changes in customer demand.

Real-time data sharing and cross-functional teams improve supply chain visibility, helping companies align inventory management and logistics planning to ensure products are available when and where customers want them. This vertical and horizontal integration across the supply chain enables businesses to deliver higher levels of customer satisfaction.

3. Rising importance of sustainability

Integrated supply chain management supports sustainability by improving resource utilization, reducing waste, and promoting responsible practices across the supply chain. As consumers increasingly prioritize eco-friendly products, supply chain managers must monitor the practices of raw material suppliers and other stakeholders involved in production.

Effective supply chain integration allows businesses to track sustainability metrics, improve energy and material use efficiency, and implement supply chain processes that align with environmental goals. This focus on sustainability reduces costs, strengthens brand reputation, and meets growing market expectations.

For more on sustainability, check out carbon footprint software/tools, digital transformation and sustainability, and sustainable management definition & best practices.

4. Rising importance of risk mitigation

The interconnected nature of global supply chains makes them vulnerable to disruptions, from natural disasters and geopolitical events to supplier failures and shifts in market demand. Integrated supply chains help companies build resilience by enabling better information sharing and improving visibility across the supply chain network.

By leveraging integrated systems and real-time data, businesses can anticipate disruptions, adjust production schedules, and coordinate with supply chain partners to maintain continuity. This proactive approach reduces supply chain lead times, optimizes inventory levels, and minimizes the impact of unforeseen events on supply chain operations.

Conclusion

Mastering supply chain integration is essential in today’s fast-changing, globally connected business landscape. Following practical, well-planned approaches, companies build supply chains responsive to shifting market demands, meet rising customer expectations, and support sustainability goals.

Effective integration helps businesses turn data into valuable insights, improve coordination among partners, and strengthen their ability to handle risks. Success comes from aligning people, processes, and technology across the network. With a steady focus on improvement, businesses can shape supply chains that deliver greater resilience, stronger performance, and lasting value.

External Links

- 1. Global supply chain management market size 2020-2026| Statista. Statista

- 2. Global supply chain management software market 2026| Statista. Statista

- 3. Case Study: Amazon’s AI-Driven Supply Chain: A Blueprint for the Future of Global Logistics - The CDO TIMES. The CDO TIMES

- 4. Case Study: Unilever's Integration of AI in the Supply Chain - AIX | AI Expert Network. AIX

- 5. Nike and the 2024 Supply Chain Disruption: A Case Study in Crisis Management - Eustochos. Eustochos

- 6. Walmart Supply Chain: How to Build an Integrated Supply Chain.

- 7. Taking a Lesson From Barbie, Mattel Builds a More Nimble Supply Chain - WSJ. The Wall Street Journal

- 8. Global supply chain management - statistics & facts | Statista. Statista

- 9. https://www.pwc.com/us/en/advisory-services/publications/consumer-intelligence-series/pwc-consumer-intelligence-series-customer-experience.pdf

- 10. https://c1.sfdcstatic.com/content/dam/web/en_us/www/documents/research/salesforce-state-of-the-connected-customer-4th-ed.pdf

![5 Supply Chain Data Sharing Barriers & Best Practices ['25]](https://research.aimultiple.com/wp-content/uploads/2023/06/Supply-Chain-Data-Sharing-1-190x107.png.webp)

Comments

Your email address will not be published. All fields are required.