Since current automation technology like RPA relies mostly on rules and custom AI modules, it:

-

Can’t adapt to changes in processes

-

Requires a significant programming and testing work to roll-out a robot.

APA aims to change this by:

-

Simplifying programming with generative AI and allowing non-developers to build AI agents

-

Self-healing AI agents that can adapt to process changes

Evolution of automation

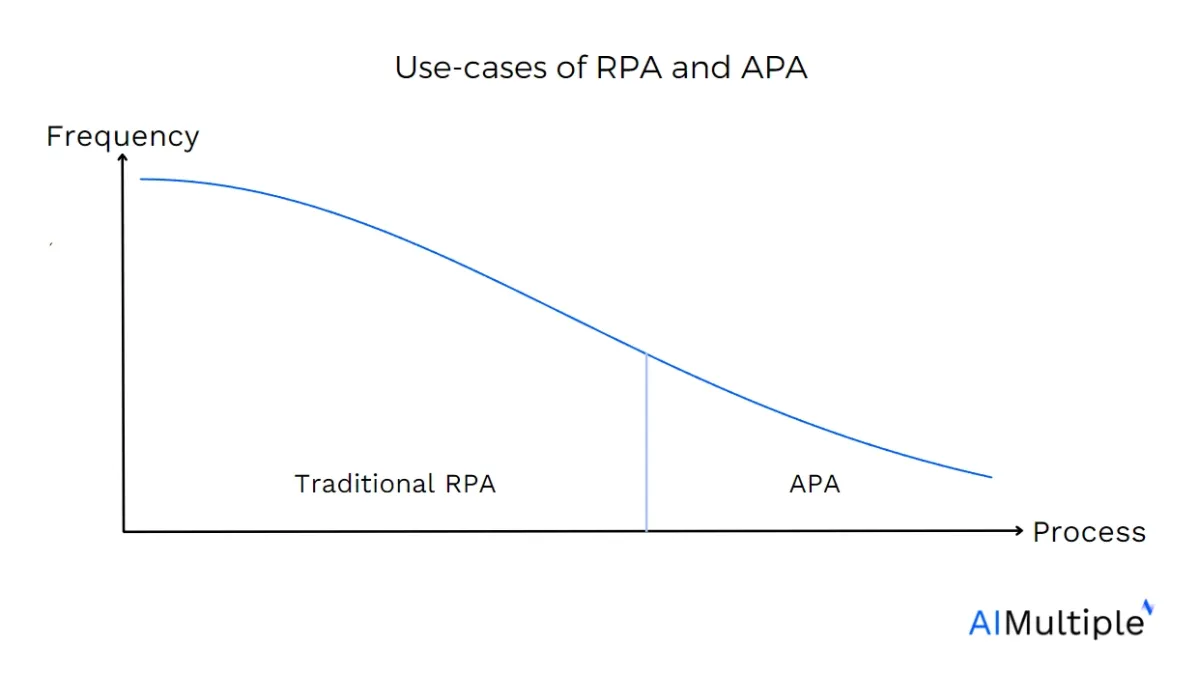

Digital automation is evolving from basic rule-based systems to sophisticated AI-driven processes.

Robotic process automation is a rule-based automation technology relying on screen scraping and APIs to interact with business systems. It is useful for automating rule-based repetitive tasks.

However, most enterprise activities can not be reduced to a set of rules. Therefore, vendors started adding machine learning modules (e.g. image recognition) to RPA bots to automate more complex processes. They called this improved automation technology as intelligent automation or cognitive automation.

While this approach has been helpful, bots still remained static and cumbersome. They break down when processes change and require maintenance.

With the rise of generative AI, vendors started adopting the term; agentic process automation (APA) or enterprise AI agents. With APA,

-

Users can prompt AI agents to take actions.

-

AI agents can attempt to solve unexpected problems during their execution thanks to the flexible nature of LLMs.

This increases the scope of enterprise automation.

How does APA work?

AI agent development

Citizen-developers with prompt engineering experience prompt AI agents about the required bot. Prompts can be used to create test cases and ensure resilience of the bot.

AI agent execution

In attended automation, employees need to use numerous bots to accelerate their work. For example, a support rep could trigger a bot to collect certain data points about a customer’s issue. However, there could be hundreds of such bots which makes it hard to manage and use them.

With APA, employees can prompt AI agents to start work on a chain of activities which would result in completion of complex tasks. These agents leverage LLMs to automate complex, dynamic workflows, autonomously constructing, executing, and adapting workflows with minimal human intervention.

This helps employees set higher level goals for machines while machines plan, use various tools, learn from feedback and complete tasks.

Real-life example:

Siemens applied artificial intelligence to streamline its document handling, automating the processing of over 35,000 delivery note formats. The system achieved 98% accuracy and enabled touchless processing for more than 90% of delivery notes within two weeks of implementation.

This shift to AI-driven automation, utilizing generative AI and large language models, significantly reduced manual work and improved efficiency in Siemens’ document management workflow.1

Benefits of agentic process automation

Agentic process automation increases:

-

The number of processes that can be automated thanks to the increased autonomy that APA brings

-

Resilience of bots since bots can rely on LLMs to resolve unexpected errors

This allows companies to get more out of typical automation benefits:

-

Efficiency: Its ability to automate complex processes results in more efficient process management in compared to the existing automation tools. Complex and dynamic workflows can be used to automate not repetitive and rule-based tasks, so APA can be used in the tasks requiring cognitive abilities, which RPA is not sufficient.

-

Flexibility: With its ability to understand and process unstructured data, agentic process automation can oversee workflows dynamically. It can use many different data and output them as wanted.

-

Accuracy: Traditional automation systems also offers a very accurate output for rule-based tasks, but in the case of complex and dynamic tasks, this changes. APA can automate tasks that require human like intelligence. Traditional automation methods will fail to give correct outputs in those algorithms, but agentic ai systems can analyze data in more complex processes.

Comparison to traditional RPA

Robotic Process Automation (RPA) involves the use of software robots to automate repetitive, rule-based tasks that are typically performed by humans. RPA relies heavily on predefined rules and scripts, making it suitable for tasks that follow a clear, unchanging set of instructions.

APA, on the other hand, leverages the power of LLMs to automate complex workflows dynamically and intelligently, offering flexibility, adaptability, and efficiency.

There are different reasons why users automate a process using RPA. These are:

-

Reducing the human errors

-

Time management

-

Cutting down the costs and increase ROI

When we compare APA and RPA, while both can be preferred in terms of speeding up the process and making it more cost effective, we see that RPA stands out more in terms of reducing the human errors thanks to its strict rule-based structure.

If a process is suitable for RPA, and not requires human like intelligence, this process is better to be automated with RPA, instead of APA because processes that are not created and audited by a human have the potential for error.

A human should check whether the bot has correctly constructed the process, how it is executed, and the outputs of the process. The strict rules of robotic process automation make it reliable and non-vulnerable.

Agentic process automation offers users a dynamic and evolving process, unlike traditional robotic process automation. Robots produce and manage processes themselves, so instead of rigid and unchangeable processes that are subject to strict rules, more flexible processes are obtained. It becomes possible for companies to automate more processes.

Implementation and challenges

APA offers seamless integration with existing systems, since users should only prompt the required process, and not have to deal with the developing the process.

Business and technology sectors should keep that in mind that APA may require significant changes to existing business processes and workflows, and these challenges requires a proactive and thoughtful approach, including rigorous testing, continuous monitoring, and ongoing training.

Real-world applications of APA

APA has broad applicability across industries, departments, and classes of processes, including banking and financial services, insurance, manufacturing, and more. It can be used to automate complex tasks, such as data analysis, customer service, and supply chain management. APA can also be used to support innovation, by analyzing vast amounts of data, identifying patterns, and making recommendations.

FAQ

What is agentic process automation (APA)?

Agentic Process Automation (APA) is a novel approach to automation that leverages AI agents to automate complex processes. APA uses large language models (LLMs), large action models (LAMs) and generative AI to enhance decision-making and execution capabilities. APA enables AI agents to interpret tasks, make real-time decisions, and continuously adapt workflows based on real-time data.

How does the future of automation look?

The future of digital automation, led by AI Agents, holds immense promise. As businesses embrace APA and integrate it with other emerging technologies, they will unlock new levels of efficiency, flexibility, and innovation.

The focus on human-AI collaboration, ethical standards, and continuous improvement will ensure that automation technologies are used responsibly and effectively. Agentic Process Automation represents a significant leap forward in the field of digital automation, offering enhanced efficiency, flexibility, and accuracy.

APA has the potential to revolutionize the way businesses operate, by automating complex business processes and freeing up human workers to focus on more creative and strategic work. By staying ahead of the curve and adapting to these advancements, organizations can position themselves for success in an increasingly automated world.

Comments

Your email address will not be published. All fields are required.