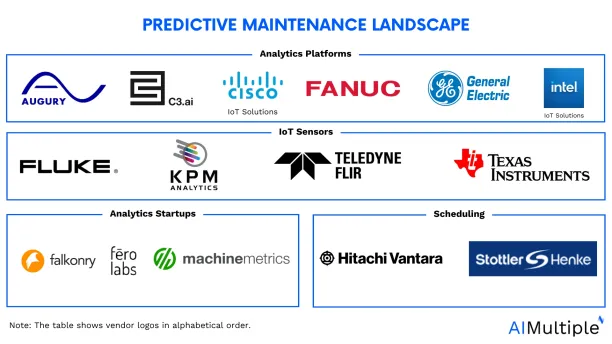

Top 15 Predictive Maintenance Tools & Selection Guide in 2024

Advances in artificial intelligence (AI) and robotics is leading to a greater reliance on industrial machines in industries like manufacturing, mining and logistics.

Predictive maintenance can identify potential sources of machine failure and direct maintenance operations to avoid downtime that would otherwise be caused by failure. Unplanned downtime costs industrial firms $50 billion annually.1 Predictive maintenance results in more productive time, reduced repair costs and human effort.

Comparison of the top 15 predictive maintenance solutions

There are >25 predictive maintenance tools, complicating the vendor selection process.

| Vendor | Type | # of Employees | Review | Year Founded | HQ |

|---|---|---|---|---|---|

| General Electric (GE) Digital | Analytics | 3,632 | 4.4/5 based on 83 reviews | 2015 | USA |

| Intel IoT | Analytics | 122,108 | 4.6/5 based on 20 reviews | 1968 | USA |

| Augury | Analytics | 388 | 4.8/5 based on 3 reviews | 2011 | USA |

| Falkonry | Analytics | 60 | 4.3/5 based on 2 reviews | 2012 | USA |

| Cisco IoT | Analytics | 99,761 | 4/5 based on 1 review | 1984 | USA |

| C3 AI | Analytics | 1,024 | 4.5/5 based on 1 review | 2009 | USA |

| MachineMetrics | Analytics | 53 | 4.5/5 based on 1 review | 2014 | USA |

| Fero Labs | Analytics | 33 | NA | 2016 | USA & Germany |

| FANUC | Analytics | 8,200 | NA | 1956 | Japan |

| Stottler Henke | Scheduling | 58 | NA | 1988 | USA |

| Hitachi Vantara | Scheduling | 12,133 | 4.3/5 based on 57 reviews | 2017 | USA |

| Texas Instruments | IoT sensors | 29,957 | 4.8/5 based on 14 reviews | 1930 (1951 as Texas Instruments) | USA |

| Fluke Corporation | IoT sensors | 3,126 | NA | 1948 | USA |

| KPM Analytics Process Sensors | IoT sensors | 224 | NA | 2015 | USA |

| Teledyne FLIR | IoT sensors | 3,290 | NA | 1978 | USA |

The table above compares predictive maintenance tools in terms of their category and user review data collected from Gartner Peer Insights and G2. The number of employee information is obtained from companies’ LinkedIn profiles. The table is sorted based on the number of reviews.

What are leading predictive maintenance tools & vendors?

IoT sensors

Sensors provide live data feeds including vibration, sonic and thermal imaging data. This data powers predictive maintenance programs. While industrial machines come with a variety of sensors, additional sensors can be installed for increased visibility into factory operations.

#1 Fluke

With Fluke infrared thermometers, manufacturers can get temperature readings from a safe distance to prevent unexpected incidents.2

#2 KPM Analytics Process Sensors

KPM Analytics Process Sensors supplies Infrared (IR) temperature sensors, thermal imaging camera systems, blackbody calibration sources, and portable thermometers for industrial processes and research applications.3

#3 Teledyne FLIR

Teledyne FLIR4 and its subsidiary brands (Raymarine,5 Extech,6 and Armasight7) provide thermal sensors for substation security and predictive maintenance.

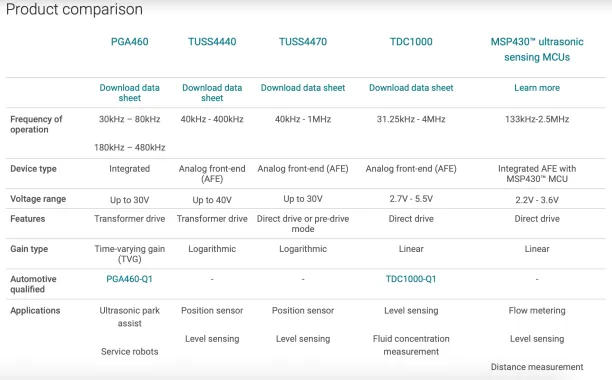

#4 Texas Instruments

Texas Instruments offers multiple sensors with different capabilities. Their ultrasonic sensor solutions are able to measure flow, level, proximity, position, imaging and distance. The below image provides a product comparison of Texas Instrument’s ultrasonic sensor solutions:

Monitoring and analytics tools

These vendors process and clean IoT and other shop floor data to produce the necessary insights for predictive maintenance. Most of these solutions also support industrial / manufacturing optimization initiatives.

#5 Augury

Augury claims to serve 100+ global manufacturers in 10 industries.8

#6 C3 AI

C3 AI’s predictive maintenance solution Reliability utilizes generative AI and natural language processing to identify equipment risks. The solution also produces insight summaries to help reduce maintenance costs and downtime to increase operational productivity and asset uptime.9

#7 Cisco IoT solutions

With Cisco IoT solutions, data analysts can perform analytics at the edge to gain industrial insight and support the predictive maintenance process.

#8 Falkonry

Falkonry highlights defense references as well as industrial ones and underlines root cause analysis capabilities of its solution.1011

#9 FANUC Zero Down Time (ZDT)

With ZDT, businesses can monitor their manufacturing process remotely using a web portal that summarizes device health, equipment utilization, and energy consumption.12

#10 Fero Labs

Fero Labs highlights its explainable (i.e. white-box) contextual machine learning service and industrial processes optimization capabilities (e.g. cost, energy consumption, scrap and raw material consumption minimization).13

#11 General Electric (GE) Digital Predix & SmartSignal

GE Digital Predix Platfrom can be used in conjunction with GE Digital Twin Software to visualize data and create dashboards.1415

#12 Intel IoT solution

Intel IoT solution implements robotics technologies that reacts to sensory and IoT inputs, and provides industrial IoT and automation insights from manufacturing machine vision technologies.16

#13 MachineMetrics

MachineMetrics allows users to develop, monitor and manage their own algorithms for predictive analytics. MachineMetrics also highlights integrations with CMMS (Computerized maintenance management system) to feed them critical machine information.17

Check our full list of predictive maintenance software.

Scheduling tools

These solutions receive input from predictive maintenance platforms regarding necessary maintenance activities. They then enable businesses to schedule regular production downtime for maintenance and repair operations. While scheduling tools coordinate teams in the field, they take into account scheduling knowledge and rules.

Maintenance periods can either be automatically suggested via automatic resource scheduling or selected via users. Users can enter domain-specific scheduling constraints using a graphical user interface.

#14 Hitachi Lumada

Hitachi Lumada highlights its Customer Co-creation Framework for production and maintenance scheduling optimization.18

#15 Stottler Henke’s Aurora

Stottler Henke’s Aurora identifies key scheduling decision points and executes sensitivity analysis to determine the optimal time and resources. It also provides a stable schedule mode to keep the previous schedule while inserting new data.19

3 classes of predictive maintenance tools

There are 1000+ tools enabling predictive maintenance in 3 categories which are described in detail below:

IoT sensors

Sensors have always been an important part of any predictive maintenance program because they allow us to monitor slight changes and make adjustments accordingly to prevent small issues from evolving into major problems including electrical equipment failure and more. Having multiple different sensors monitoring different metrics can be key to getting a better understanding of your processes and preventing early failures and the resulting downtime they cause.

Sensors enabling vibration, sonic, and ultrasonic analysis

System components undergo normal wear, stress, and strain that are then indicated in its vibration and frequencies. Most components have a ‘normal’ frequency and deviation from this standard indicates conditions that may lead to failure if left untreated.

Unexpected vibrations can be fatal to a machine. In the highly technical sport of Formula One, for example, Honda’s engines faced unexpected vibration issues. These issues were so severe that the engines would literally shake themselves to death, failing (often spectacularly) in the middle of a competition. Even if it is not Formula 1, vibration related failures would still cause downtime.

Vibrations can occur due to any number of factors. A machine’s bearings or brackets might start to lose their tactile strength. A component may be nearing the end of its lifespan. Upon analysis, technicians (if needed) or learning machines will determine the appropriate course of action, and when possible, take it as needed.

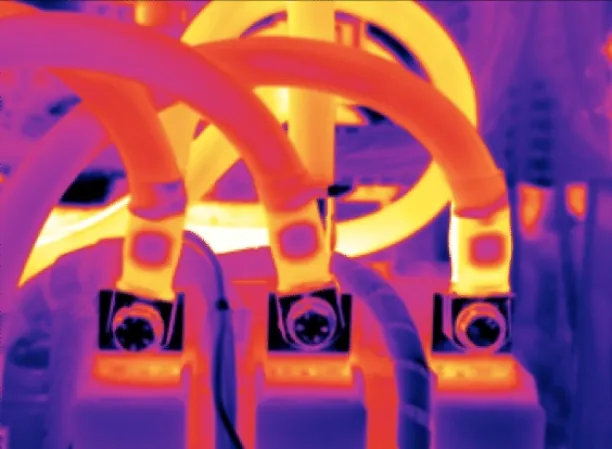

Thermal Imaging Sensors

Excessive heat is a death sentence for metals, composites and electronics. It is a major threat to electric motors20 and a primary maintenance concern for telecom companies.21 Dangerous working conditions and catastrophic delays can occur due to something as simple as a poorly lubricated set of bearings. Thermal imagery utilizes infrared images to monitor temperatures of interacting machine parts – allowing any abnormalities to quickly become apparent. As with other change-sensitive monitors, they trigger scheduling systems which would then lead to the appropriate action being taken automatically in order to prevent component failure.

Simple thermal imagery equipment is easy to get and easy to operate. In its simplest form, technicians can take mobile readings with a handheld device. There is no downtime required for a simple handheld thermal image scan. The positives to this sort of predictive maintenance solution are simplicity and ease. The downside is that constant observation is likely impossible with a handheld device.

A more sophisticated and accurate system would need diagnostic thermal tools with connectivity. Compared with baseline data, this equipment would show abnormal temperature ranges. These sensors would track the machines and collect data for potential deviations from acceptable temperatures. Once relayed, that information would alert technicians to any issues. This system would need greater capital investment and technologically competent staff.

Oil & lubricant sensors

Oil analysis can determine many factors about machine performance. Actual oil viscosity versus expected viscosity can show how your machine is preventing oxidation, dilution and moisture. Metal shards in the oil can alert technicians to parts grinding that might slow or break a machine. Sensors that calculate fluid dynamics might help expose a leak or faulty connector.

Analytics systems are commonly designed to detect impurities in oil. Metal, dirt and sludge will be easily found. Moisture is easily detected, even in trace amounts. Your system will calculate any aspect of the oil which could cause failure.

Oil analytics systems have been around for a while. Most modern cars have them integrated into the central computer system. Your car checking oil quality is a practical example of a predictive maintenance system.

These systems are not difficult to integrate into existing machines. You should have guidance from your lubricant provider on acceptable temperatures and viscosity. You could cross-reference your actual results against the expected results.

Predictive maintenance sensors best practices

Regardless of what kind of sensor your organization requires in order to be successful, there are a few best practices to keep in mind during implementation:

- Ensure the accurate orientation and aim of any device by minimizing exterior conditions that could otherwise lead to incorrect readings.

- Build a long-term imaging plan based on factors such as reliability demands, component-specific findings, budget considerations, manufacturer recommendations and similar.

- Invest in training or consider bringing in outside assistance to ensure the correct usage of the tool by employees.

- To be more cost effective, be sure to take a baseline reading from which you can compare changes over time – this can ultimately help in justifying your initial cost to stakeholders.

- Encourage full participation throughout your organization to get a balanced perspective from different levels of responsibility and expertise.

- Remember that having multiple diagnostic tools working together can help to prevent a greater number of failures, and in the case of failure, to better pinpoint exactly what was the cause.

- Ensure that your sensors automatically feed data into your analytics and monitoring systems.

Monitoring and analytics tools

Industrial analytics is often considered to be an integral part of the ‘fourth industrial revolution’, which is characterized by the convergence between traditional industrial practices and modern IT improvements. These advances include data analytics and their related interpretation via machine learning, and also advances in connectivity through IoT. What this means practically speaking is that a greater number of decisions and actions are starting to become based on measurable data that can be acted upon quickly.

One important part of this field includes IoT sensors to monitor key changes in components. To meet the increasing demand for these technologies, a wide range of options are available to help industrial businesses find success – no matter the need or function. Monitoring tools work by utilizing advanced algorithms and machine learning in a way that enables them to take action in real-time.

Some examples of industrial analytics and monitoring in action include:

- Predictive maintenance on equipment, machinery, and assets

- Specific machine parameter optimization

- Decision support systems

- Condition monitoring of assets

- Supply chain optimization

Once you understand the problem you are trying to solve with monitoring tools, such a solution generally functions in the following manner:

- Get data feeds: sensors and data storage, programmable controllers, manufacturing execution systems, BMS, manual data, external data from APIs and similar.

- Process data feeds which many involve data cleaning or reformatting.

- Enrich this data by connecting it with other meaningful and relevant data sets.

- Optional: In case of manual analytics, visualize the data with the help of data science or data team tools that enable staff to understand and make use of the data.

- Generate recommendations which can be maintenance suggestions or process improvement suggestions.

These activities can lead to larger and more consolidated data sets that can support deeper analytics and better decision making. You can experience other benefits throughout the supply chain and order fulfillment processes.

Best practices for ensuring the success of any IoT or similar analytical solutions:

- Develop an effective IoT framework that is collaborative and enables usage of the right resources when needed.

- Consider working in a cloud environment so that stakeholders across locations can get the most from the data.

- Choose technology partners that understand the unique challenges related to industrial environments.

Schedulers

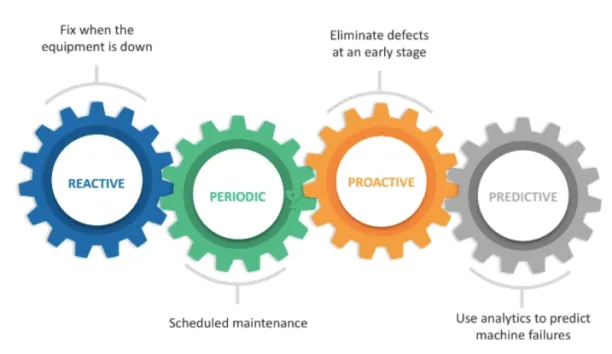

Remember that predictive maintenance is about monitoring equipment and acting only when necessary. Technology programs designed for industry are honing in on precisely when action is required.

These available systems will automate much of the maintenance analysis. Your system will not be able to change parts, but it will be able to alert technicians of a pending issue. These systems can request maintenance long before a machine faces failure. When a machine starts to decrease in productivity or output, proactive maintenance can occur.

These modern versions of a traditional solution work by automating much of the maintenance analysis traditionally managed by a person. This person, who previously would have analyzed multiple inputs, ongoing processes, and other relevant factors needed for building an effective maintenance schedule, can then focus their energies on the results of any changes or adjustments that were made.

By utilizing the right scheduling tools for your organization, the following results can be realized:

- Assign resources and schedule activities based on a wider range of external and internal factors.

- Optimization of production schedules proactively, based on learned models in the past.

- Apply countermeasures much sooner when possible, increase the changes to balance any issues that may arise.

- Detect bottlenecks in separate departments and practices that may be impacting other seemingly unrelated processes.

Best practices to help manufacturers achieve a successful implementation of any scheduling tool:

- Deliver ideal production schedules that managers can choose from based on priority.

- Determine ideal production and workflow velocity to achieve the right balance of quality and quantity.

Recommendations for working with predictive maintenance tools

For manufacturers and other industrial organizations, finding the best way to minimize waste and inefficiency can have a major impact on the bottom line of your business.

Whole is greater than the sum of its parts. By combining sensor feeds with clean historical data on analytics platforms integrated to the scheduling system, industrial firms can reap these benefits. However, investing in only a part of the solution (e.g. analytics) may not result in substantial savings.

Human factor is key. Maintenance crews have years of experience working with machines. Instead of blindly following machine recommendations, businesses are advised to combine these insights with human expertise for optimal outcomes.

If you are looking for AI problems or need to figure out your AI strategy:

External sources

- 1. “How manufacturers achieve top quartile performance,”. IndustryWeek and Emerson. Revisited January 31, 2024.

- 2. “Fluke Industrial Electrical Test Tools | Thermal Imaging | Calibration“. Fluke. Retrieved February 5, 2024.

- 3. “Infrared Temperature Measurement | Process Sensors Corp – IR Temperature Sensors“. Process Sensors Corporation. Retrieved February 5, 2024.

- 4. “Thermal Imaging, Night Vision and Infrared Camera Systems | Teledyne FLIR“. Teledyne FLIR. Retrieved February 5, 2024.

- 5. “Marine Electronics for Boats, Boating Electronics | Raymarine“. Raymarine. Retrieved February 5, 2024.

- 6. “Extech is now on FLIR.com | Teledyne FLIR“. Teledyne FLIR. Retrieved February 5, 2024.

- 7. “Thermal & Night Vision Scopes, Optics & Goggles | Armasight“. Armasight. Retrieved February 5, 2024.

- 8. “Why Augury“. Augury. Retrieved February 8, 2024.

- 9. “Implement AI-Powered Predictive Maintenance in Weeks“. C3. Accessed February 7, 2024

- 10. “Falkonry | Time Series AI Suite“. Falkonry. Retrieved February 5, 2024.

- 11. “Falkonry | Time Series AI Suite“. Falkonry. Retrieved February 5, 2024.

- 12. “Zero Down Time (ZDT) | FANUC America“. FANUC. Retrieved February 5, 2024.

- 13. “Industrial Process Optimization Software for Profit and… | Fero Labs“. Fero Labs. Retrieved February 5, 2024.

- 14. “GE Predix Platform | Industrial IoT Platform | GE Digital“. GE Digital. Retrieved February 5, 2024.

- 15. “Equipment Downtime Prevention | GE SmartSignal – Predictive Analytics Software“. GE Digital. Retrieved February 5, 2024.

- 16. “Internet of Things (IoT) Solutions – Intel“. Intel. Retrieved February 5, 2024.

- 17. “Predictive Maintenance Manufacturing | MachineMetrics“. MachineMetrics. Retrieved February 5, 2024.

- 18. “Lumada: Hitachi Global“. Hitachi. Retrieved February 5, 2024.

- 19. “Aurora | Stottler Henke Associates, Inc.“. Stottler Henke. Retrieved February 5, 2024.

- 20. “Overheating Electric Motors: A Major Cause of Failure”. EP. April 1, 2003. Revisited January 31, 2024.

- 21. “Extreme Heat Report” (PDF). IFRC. October, 2022. Revisited January 31, 2024.

Cem has been the principal analyst at AIMultiple since 2017. AIMultiple informs hundreds of thousands of businesses (as per similarWeb) including 60% of Fortune 500 every month.

Cem's work has been cited by leading global publications including Business Insider, Forbes, Washington Post, global firms like Deloitte, HPE, NGOs like World Economic Forum and supranational organizations like European Commission. You can see more reputable companies and media that referenced AIMultiple.

Throughout his career, Cem served as a tech consultant, tech buyer and tech entrepreneur. He advised businesses on their enterprise software, automation, cloud, AI / ML and other technology related decisions at McKinsey & Company and Altman Solon for more than a decade. He also published a McKinsey report on digitalization.

He led technology strategy and procurement of a telco while reporting to the CEO. He has also led commercial growth of deep tech company Hypatos that reached a 7 digit annual recurring revenue and a 9 digit valuation from 0 within 2 years. Cem's work in Hypatos was covered by leading technology publications like TechCrunch and Business Insider.

Cem regularly speaks at international technology conferences. He graduated from Bogazici University as a computer engineer and holds an MBA from Columbia Business School.

To stay up-to-date on B2B tech & accelerate your enterprise:

Follow onNext to Read

Predictive Maintenance (PdM): Benefits & How it Works in 2024

Predictive vs Preventive: In-depth Maintenance Guide for 2024

Predictive maintenance is always an interesting topic to read and discuss and today we have advanced data analytics to analyze when, where and how things will break. Having said that, innovators are coming up with damn good e-maintenance system integrated advanced techniques for diagnosis. machine downtime tracking tools like Thrive are providing real-time data and reporting, that is eventually helping in decision making.

Comments

Your email address will not be published. All fields are required.