Top 6 Benefits of CMMS for Maintenance Operations in 2024

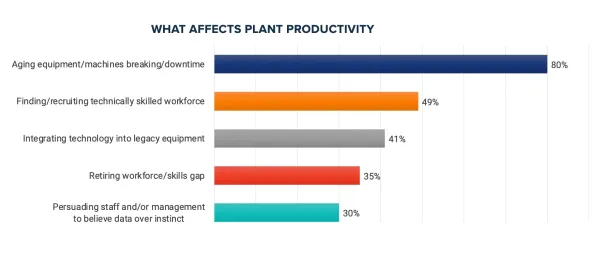

Effective asset maintenance is essential for industries like manufacturing, utilities, mining, and healthcare that are asset-intensive. According to the 2022 Industrial Maintenance Report, 80% of maintenance managers say unexpected downtime due to aging equipment or machines breaking down is the biggest factor affecting plant productivity.

According to the same report, computerized maintenance management systems (CMMS) are among the top technologies maintenance operators use or plan to use for managing assets, their parts, and maintenance histories. In this article, we’ll explore six benefits of using a CMMS for maintenance operations.

1. Centralizes maintenance-related knowledge

The main function of a CMMS is centralizing the maintenance information of physical assets. The database of CMMS stores information such as:

- Asset manufacturer, model, and serial number,

- Asset performance statistics,

- Asset documentation and manuals,

- Maintenance work orders,

- Maintenance schedules,

- Work order type,

- The responsible maintenance worker for work orders.

By storing and providing access to this information, a CMMS:

- Makes maintenance resources available to all stakeholders,

- Standardizes maintenance processes across the business,

- Enables data-driven decisions about asset maintenance.

2. Enables predictive maintenance

In addition to what a CMMS stores in its database, businesses can integrate their CMMS with other company systems such as SCADA, Industrial Internet of Things (IoT), or ERP. Integrating these systems enables them to share information with each other in real time. Through these integrations, a CMMS can:

- Leverage real-time data from sensors or meters installed on equipment,

- Predict upcoming asset failures by combining real-time data from assets and other asset information such as age, maintenance history, etc.,

- Automatically create work orders and schedule and assign maintenance tasks,

- Provide information about inventory availability of replacement parts through ERP system integration.

With these features, businesses can shift to a predictive maintenance strategy instead of preventive maintenance, which involves performing routine maintenance at regular intervals and often results in over- or under-maintenance.

3. Streamlines work order and inventory management processes

Since a CMMS constitutes a centralized hub for all maintenance-related information through its database and its integrations with other company systems, it can be used to automate and streamline end-to-end maintenance processes. As we discussed in the previous section, a CMMS can automate the process of creating work orders, scheduling maintenance, and assigning employees to maintenance tasks based on triggers. Moreover, it can

- Track maintenance, repair, and operations (MRO) inventory levels, leverage inventory forecasting methods, and automatically order replacement parts,

- Prioritize work orders and shift maintenance schedules,

- Facilitate maintenance knowledge transfer by guides, photos, videos, etc.,

- Provide mobile connectivity for field workers,

- Automatically log maintenance data such as parts used or time to conduct maintenance.

Streamlining work order management and MRO inventory management processes helps businesses improve productivity, save time, and reduce costly errors. For instance, by effectively managing the MRO inventory, businesses can save up to 30% of annual inventory spending.

4. Reduces downtimes

Unplanned downtimes cost industrial manufacturers up to $50 billion per year due to factors such as extra labor to solve the issue, wasted materials, and lost revenues. There is no way to avoid downtimes completely since assets require maintenance. However, a CMMS helps businesses limit downtimes and their associated costs by:

- Increasing asset visibility,

- Preventing equipment failures through predictive maintenance,

- Increasing maintenance efficiency through automation,

- Preventing unnecessary or over-maintenance.

For instance, Perth County Ingredients, a food products supplier, decreased reactive maintenance and associated downtime by 54% and saved over $40 thousand a year by implementing a CMMS.1

5. Increases worker safety

A CMMS allows storing safety checklists, repair manuals, and photos or videos about maintenance procedures and enables accessing this information through mobile devices. Since it can collect real-time asset data, it can also alert staff in case of equipment failure that could endanger field workers.

These features make safety procedures readily available to operators and reduce safety violations, which can result in penalties of up to $145,000 per violation for willful or repeated violations.

6. Improves regulatory compliance

A CMMS can help businesses improve regulatory compliance and avoid fines by:

- Automatically generating audit reports with the required information as it stores and documents all maintenance data. Check our article on report automation for more on this topic,

- Decreasing OSHA violations by increasing the accessibility of safety procedures for field workers.

For instance, Secant Group, a medical technology manufacturer, increased its compliance level from 50-60% to 90% across all its sites by implementing a CMMS solution.2

Further reading

- Manufacturing Digital Transformation: Top Trends & Technologies

- Top 7 Use Cases of Intelligent Automation in Manufacturing

- Manufacturing analytics: $6T opportunity

If you have other questions about CMMS or the use of digital technologies in asset management, we can help:

Sources

Cem has been the principal analyst at AIMultiple since 2017. AIMultiple informs hundreds of thousands of businesses (as per similarWeb) including 60% of Fortune 500 every month.

Cem's work has been cited by leading global publications including Business Insider, Forbes, Washington Post, global firms like Deloitte, HPE, NGOs like World Economic Forum and supranational organizations like European Commission. You can see more reputable companies and media that referenced AIMultiple.

Throughout his career, Cem served as a tech consultant, tech buyer and tech entrepreneur. He advised businesses on their enterprise software, automation, cloud, AI / ML and other technology related decisions at McKinsey & Company and Altman Solon for more than a decade. He also published a McKinsey report on digitalization.

He led technology strategy and procurement of a telco while reporting to the CEO. He has also led commercial growth of deep tech company Hypatos that reached a 7 digit annual recurring revenue and a 9 digit valuation from 0 within 2 years. Cem's work in Hypatos was covered by leading technology publications like TechCrunch and Business Insider.

Cem regularly speaks at international technology conferences. He graduated from Bogazici University as a computer engineer and holds an MBA from Columbia Business School.

To stay up-to-date on B2B tech & accelerate your enterprise:

Follow on

Comments

Your email address will not be published. All fields are required.